What software should be used for laser cutting?

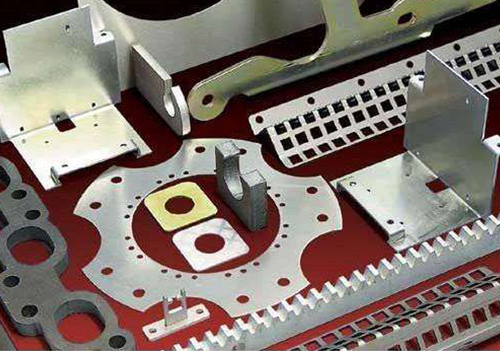

The first is CAD software, CAD is a kind of software that can make two-dimensional and three-dimensional graphics. The two-dimensional drawings made by CAD software can be set very high in accuracy to ensure the accuracy of cutting. And the two-dimensional drawings made by CAD are composed of lines, and these lines are the roadmap of laser cutting, and CAD also has the detection of line segment closure. If the line segment is not closed, the laser cutting machine cannot cut it, so we can avoid a series of problems through CAD. So when a workpiece needs to be laser cut, the first thing to do is to make the cut drawings through CAD, and then export them to the dxf format file.

The reason why we need to export the file of the dxf pattern is because most of the programming software that comes with the laser cutting machine only recognizes the file of this pattern. After we make the graphics with CAD, we need to import the dxf file into the programming software, and then generate the cutting path one by one. After generating the cutting path, it can be directly imported into the device for use. Of course, if the cutting drawings are more complicated, the cutting path generated by one click may not be suitable, and we need to make manual adjustments, including the selection of the opening path of the hollow part and the reserved part. How to make the device take the shortest path can also improve the cutting speed.

The above two are the necessary two kinds of software for laser cutting processing. The reason why the software that comes with the equipment is not used is because the function is incomplete. If it is not suitable for making drawings, it is slow and prone to problems. And CAD can make up for this shortcoming very well. The combination of these two software can also be called nesting software. Of course, the software that exports the drawings required by the equipment does not necessarily have to come with its own software. There are still many software that can be replaced on the market.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole