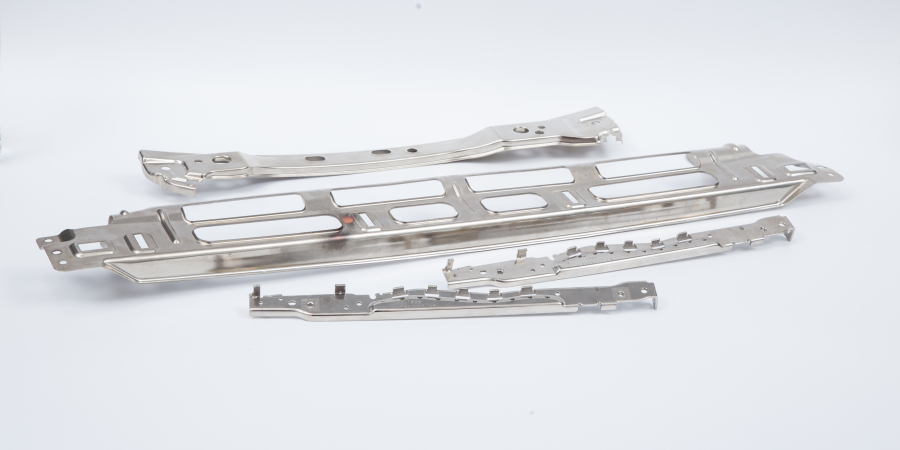

The formation of Metal Stamping parts is mostly caused by dust or iron filings attached to the appearance of raw materials or molds. So how can we avoid this situation?

1. Inspection and correction of the drawing die of the metal stamping die: The drawing die needs to be checked and maintained regularly to reduce the occurrence of bumps and bumps and maintain a stable state. The usual practice is to use samples to check the bonding scratches of the blank holder and the condition of the machined surface (die fillet, punch fillet);

2. Inspection and correction of cutting dies for metal stamping dies: The reason for the bumps and bumps after the shearing process is that iron powder occurs during the shearing process, so it is necessary to observe the iron powder before stamping to prevent bumps and bumps;  3. Appropriate manipulator speed: For semi-automatic drawing die production, when the drawing punch is in the lower die orientation and the manipulator speed is very fast, the burr will fall on the upper part of the punch, causing bumps and bumps. In order to prevent this problem, we can do the discharge experiment of the part before production, and reasonably set the speed and discharge angle of the manipulator so that it will not touch the part and the lower die;

3. Appropriate manipulator speed: For semi-automatic drawing die production, when the drawing punch is in the lower die orientation and the manipulator speed is very fast, the burr will fall on the upper part of the punch, causing bumps and bumps. In order to prevent this problem, we can do the discharge experiment of the part before production, and reasonably set the speed and discharge angle of the manipulator so that it will not touch the part and the lower die;

4. Check the cutting surface: When cutting the coil, the wear and damage of the cutting die will cause many tiny iron powders to adhere to the edge, so it is necessary to check the double cutting surface in the material area or stamping line before stamping production, and clean the sheet in time to remove burrs.

5. Check the sheet cleaning device: Before the production of metal stamping parts, it is necessary to check and trim the cleaning arrangement at the same time, so that it may be more effective to clean the sheet, which is also very much needed, and also need to pay attention to the roller gap and the quality of the cleaning oil. The detailed method is to apply red paint on a steel plate and make it go through the cleaning arrangement. At that time, check the shape of the antecedent of the red paint being revoked. If the removal rate is unqualified, it is necessary to check and trim the cleaning arrangement. When the cleaning oil is missing, it must be reduced in time.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole