In order to adapt to the processing of polyhedron and curved parts, foreign numerical control machine tools have adopted multi-axis machining technology very early, including five-axis linkage function. Also in China, the manufacturing industry is constantly intelligent with fierce market competition, and with the continuous development and popularization of numerical control technology, five-axis machining technology has been increasingly widely needed and applied. As the basis of modern intelligent manufacturing technology, numerical control processing technology has made extremely significant changes in the production and manufacturing process. Compared with traditional processing and manufacturing technology, five-axis numerical control processing technology highlights its significant intelligent advantages in terms of processing range, processing technology, processing process, or production cycle, processing equipment and process fixture equipment. Five-axis processing technology products are widely used in aerospace, military, medical, construction, bridges, electronics, agriculture, machinery, automobiles, industrial modeling and other industries. 1. Application in the aerospace field Due to the characteristics of aviation products with complex types, small batches, diversification, complex structure and integrity, the processing of such products is difficult, the processing process is complex, and thin-walled and large parts need to be processed. And the product quality requirements are high. Therefore, five-axis machining has become the main equipment for processing in the aviation field. In the manufacture of the side wall connecting the rib plate and the negative geometric angle of the strength rib plate, it is necessary to control the angle of the tool axis vector in multi-axis linkage to achieve effective cutting. Moreover, five-axis machining can cut the tools in the cutting process with good geometric shape to obtain high surface quality, machining accuracy and machining efficiency.  2. In the machining before the application in the field of machinery manufacturing and molds, most of the vertical machining centers are used to complete the milling of workpieces. With the continuous development of machinery and mold manufacturing technology, the limitations of vertical machining centers have become more and more obvious. Most mold processing uses a ball end milling cutter, but if a vertical machining center is used, the linear speed of the bottom surface is zero, and the surface roughness of the machined bottom surface is very poor. Five-axis machining can perform negative surface milling and can freely control the tool axis vector, thus effectively improving the milling efficiency and quality of the curved surface. In addition, five-axis machining technology also solves the processing problems such as the height and depth of the medium-sized core and cavity of large molds, especially in the automotive manufacturing industry, which is widely used.

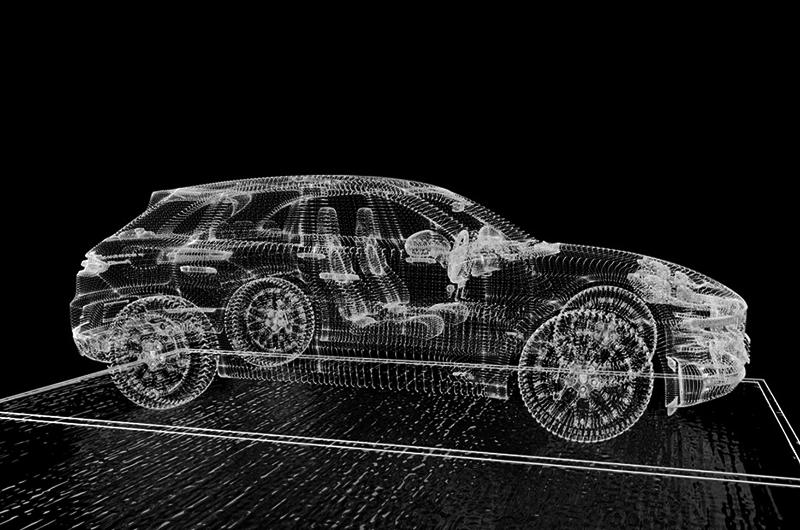

2. In the machining before the application in the field of machinery manufacturing and molds, most of the vertical machining centers are used to complete the milling of workpieces. With the continuous development of machinery and mold manufacturing technology, the limitations of vertical machining centers have become more and more obvious. Most mold processing uses a ball end milling cutter, but if a vertical machining center is used, the linear speed of the bottom surface is zero, and the surface roughness of the machined bottom surface is very poor. Five-axis machining can perform negative surface milling and can freely control the tool axis vector, thus effectively improving the milling efficiency and quality of the curved surface. In addition, five-axis machining technology also solves the processing problems such as the height and depth of the medium-sized core and cavity of large molds, especially in the automotive manufacturing industry, which is widely used.  3. Application in the field of processing in the automotive industry The shape of the impeller of the automobile turbocharger is complex, the blade is twisted, and the processing interference is very easy to occur during processing. The early processing method not only has low processing efficiency, but also poor impeller quality. Numerical control technology processing has made the processing technology of the impeller leapfrog development. The use of five-axis machining can control the space state of the tool, and through synchronous machining, a good cutting position on the tool is always involved in the processing, which improves the surface accuracy of the overall impeller and the work efficiency of the impeller in use.

3. Application in the field of processing in the automotive industry The shape of the impeller of the automobile turbocharger is complex, the blade is twisted, and the processing interference is very easy to occur during processing. The early processing method not only has low processing efficiency, but also poor impeller quality. Numerical control technology processing has made the processing technology of the impeller leapfrog development. The use of five-axis machining can control the space state of the tool, and through synchronous machining, a good cutting position on the tool is always involved in the processing, which improves the surface accuracy of the overall impeller and the work efficiency of the impeller in use.  4. Application in the field of medical apparatus With the rapid development of the national economy, people‘s living standards continue to improve, artificial joints, artificial teeth have been widely used in the lives of the general population, and the processing of these shaped parts, five-axis machining has played an indispensable role.

4. Application in the field of medical apparatus With the rapid development of the national economy, people‘s living standards continue to improve, artificial joints, artificial teeth have been widely used in the lives of the general population, and the processing of these shaped parts, five-axis machining has played an indispensable role.  5. Application in the field of special-shaped parts and artwork modeling A numerical control machine tool with five axes is actually three linear axes and two rotary axes. During the machining process, different tools can cut positions that cannot be cut by three-axis and four-axis machines. Especially for special-shaped parts with asymmetrical graphics and whose reference is not on a plane, it can be processed by five-axis machines. It is very convenient. Therefore, five-axis machining is widely used in the processing of special-shaped parts and the prototype engraving of artworks.

5. Application in the field of special-shaped parts and artwork modeling A numerical control machine tool with five axes is actually three linear axes and two rotary axes. During the machining process, different tools can cut positions that cannot be cut by three-axis and four-axis machines. Especially for special-shaped parts with asymmetrical graphics and whose reference is not on a plane, it can be processed by five-axis machines. It is very convenient. Therefore, five-axis machining is widely used in the processing of special-shaped parts and the prototype engraving of artworks.

Hello! Welcome to EMAR company website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole