What is a stamped part?

Stamped parts: The most commonly used part in hardware processing, refers to the molds used for steel/non-ferrous metal and other sheets at room temperature, which are formed into a specified shape by providing the required pressure for processing by a press.

Including some electronic devices, automotive parts, decorative materials, and so on. The stamping parts we usually refer to are cold stamping parts. For example, if you want to turn an iron plate into a fast food plate, you need to first design a set of molds. The working surface of the mold is the shape of the plate, and when you press the iron plate with the mold, it becomes the plate you want. This is cold stamping, which directly uses the mold to stamp the hardware material.

Stamped parts are widely used in daily life and are also an important component of procurement categories in many enterprises.

What are the basic processes for making stamping parts?

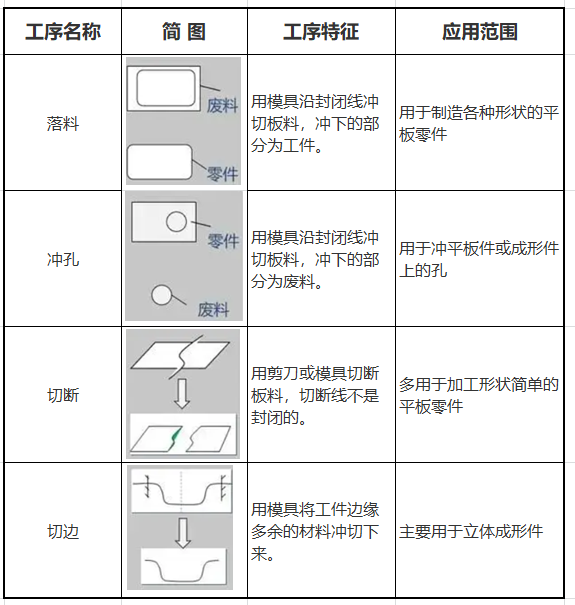

1. Separation process

Figure 1

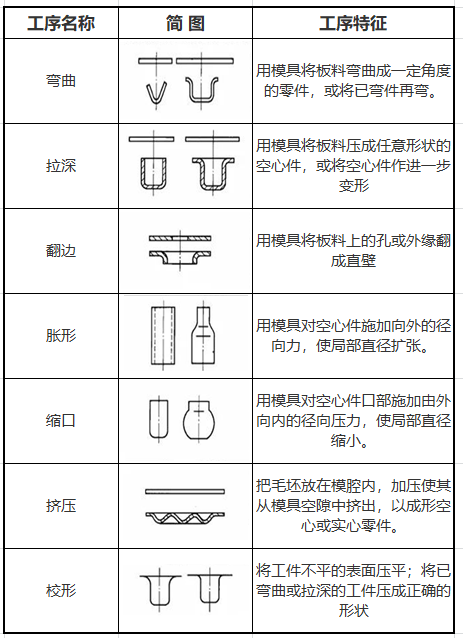

2-Forming process

Figure 2

Figure 2

How to calculate the cost of stamping parts?

1. Empirical calculation method

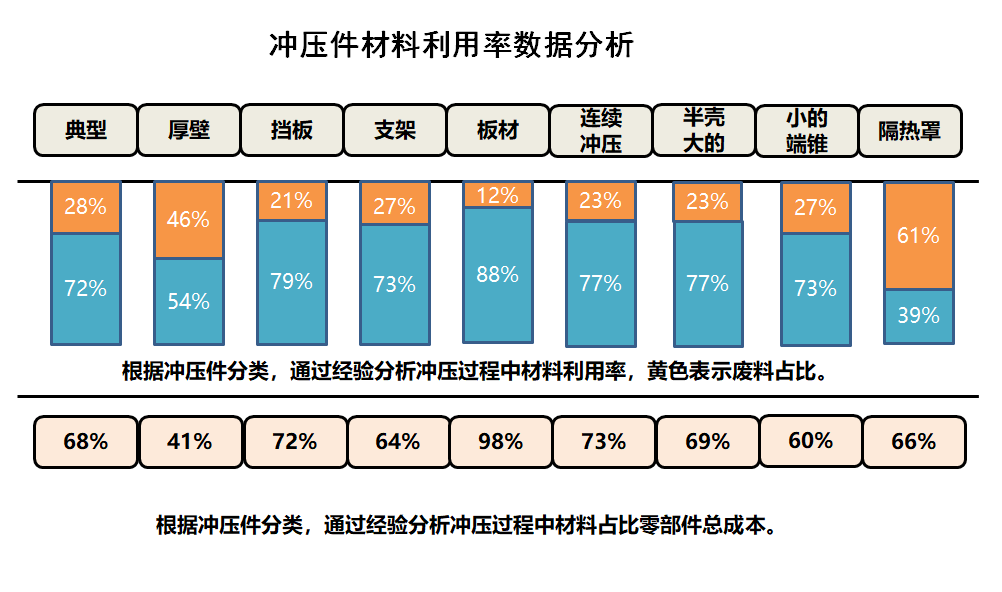

To clearly calculate the cost of components, it is necessary to know the factors that affect the cost. Based on the classification of stamping parts and empirical analysis of data, the following figure shows:

Figure 3

Figure 3

As shown in the above figure, a preliminary estimate of the price of the components requires a clear understanding of the net weight of the components in the drawings. The initial weight of the materials to be cut should be calculated based on the categories above. The material cost of the components should be determined based on the market cost of the materials. The cost of raw materials can be preliminarily calculated based on the percentage of the material cost in the above figure.

2-Process splitting method

According to Figure 1 and Figure 2 above, the machining process of the components is subdivided and studied without the need for stamping processes. Starting from the stamping and layout diagram of the components, calculate the actual material utilization rate of each component in the production process. Calculate the cost of each process based on the process of a component, plus packaging and transportation, management costs, and mold costs (usually negotiated and settled based on dimensions in the early stages of project development, or the mold costs generated are shared among the components according to 500010000).

The empirical calculation method commonly used for price estimation is sufficient, while the second method needs to consider factors such as regional labor wages, equipment models, and enterprise scale, all of which affect product prices. The impact needs to be verified and verified on site for accuracy!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque