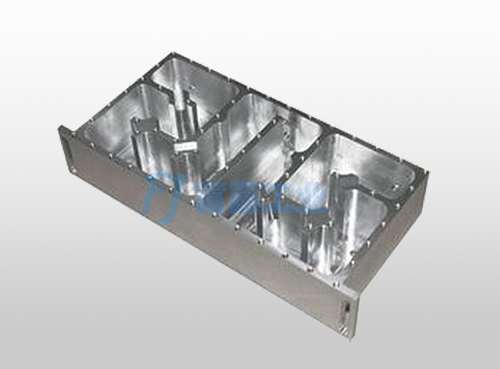

In the machining process of an enterprise, in order to reduce machining errors and improve work efficiency, fixtures are used for auxiliary processing and production. As an indispensable and important component in process production, fixtures play a very important role, whether it is processing equipment or the choice of processing scheme. In the mass production process, in order to improve the qualified rate and production efficiency of parts, we can use special fixtures. It can not only improve the accuracy of parts, but also reduce labor intensity and improve economic benefits.

Special machine tool fixture: Special machine tool fixture is a fixture specially designed and manufactured for a certain process of a workpiece. Special machine tool fixture is suitable for applications where the product is relatively stable and the output is large.

Therefore, the special fixture is an important process equipment in precision machining, and its proposed demand meets the mass production. In order to improve the production efficiency and economic benefits of the precision machining of the product in the mass production process, a special fixture is designed for the numerical control center of the machining part.

When careful precision machining on numerical control equipment, it is generally used to position two holes on one side, and the corresponding positioning elements on the fixture are two pins on one side. In order to avoid interference during the installation of the workpiece due to over-positioning, one of the two pins should be used. In the fixture design process, it is necessary to consider whether the workpiece is positioned, avoid under or over-positioning, ensure the precision of precision machining, shorten the clamping time, improve labor productivity, expand the range of machine tools, realize multi-function of one machine, easy operation, reduce labor intensity, and reduce the technical requirements of workers. The design includes some auxiliary components such as positioning devices, clamping devices, and tool guide elements. The fixture design requires two pins on one side to be positioned, one pin is designed to be round, the other pin is designed to be rhombus, and the two pins are also designed with elastic positioning pins, which can not only eliminate the error of the blank hole, but also ensure the reliable positioning.

When careful precision machining on numerical control equipment, it is generally used to position two holes on one side, and the corresponding positioning elements on the fixture are two pins on one side. In order to avoid interference during the installation of the workpiece due to over-positioning, one of the two pins should be used. In the fixture design process, it is necessary to consider whether the workpiece is positioned, avoid under or over-positioning, ensure the precision of precision machining, shorten the clamping time, improve labor productivity, expand the range of machine tools, realize multi-function of one machine, easy operation, reduce labor intensity, and reduce the technical requirements of workers. The design includes some auxiliary components such as positioning devices, clamping devices, and tool guide elements. The fixture design requires two pins on one side to be positioned, one pin is designed to be round, the other pin is designed to be rhombus, and the two pins are also designed with elastic positioning pins, which can not only eliminate the error of the blank hole, but also ensure the reliable positioning.

Machine tool fixtures are divided into two categories according to the generalization of use. One type is general-purpose fixtures, such as ordinary pliers, indexing heads, etc., which have the advantage of strong adaptability. The disadvantage is that they can only clamp regular workpieces, mostly manual clamping, which is inefficient and suitable for the production of regular single-piece and small-batch precision machined parts. The other type is a fixture specially designed and manufactured for a certain part or a certain process, because they are special, called special fixtures, which are suitable for small and medium-sized batch production or large-scale production.

Different types of machine tools have different fixture structures. Fixtures can be divided into lathe fixtures, drilling machine fixtures, milling machine fixtures, boring machine fixtures, grinding machine fixtures, and combined machine tool fixtures. Fixtures can be divided into different categories.

No matter what the classification is, a clear understanding of the definition of the fixture and the determination of the relative positional relationship between the workpiece and the tool and the machine tool can ensure the machining accuracy, quickly position and clamp the workpiece, reduce the auxiliary time and improve the production efficiency. Fixture refers to the device used to fix the machining object during the mechanical manufacturing process to make it occupy the correct position for construction or inspection, also known as fixture (qij). Understanding the definition of fixture allows us to know more clearly our needs for fixtures.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole