With the continuous development of the times, there are more and more manufacturers engaged in the processing of precision mold parts in the market. Under such circumstances, how can purchasers choose precision mold parts processing manufacturers?

Next, let‘s take a look at how to choose!

1. Engineering prototype capability

1. Engineering prototype capability

It is necessary to have an engineering prototype team with strong comprehensive skills and fast response speed, specializing in the early proofing and process exploration and improvement of customers, and to record, accumulate and optimize the processing technology at this stage, providing experience and data support for the mass production stage.

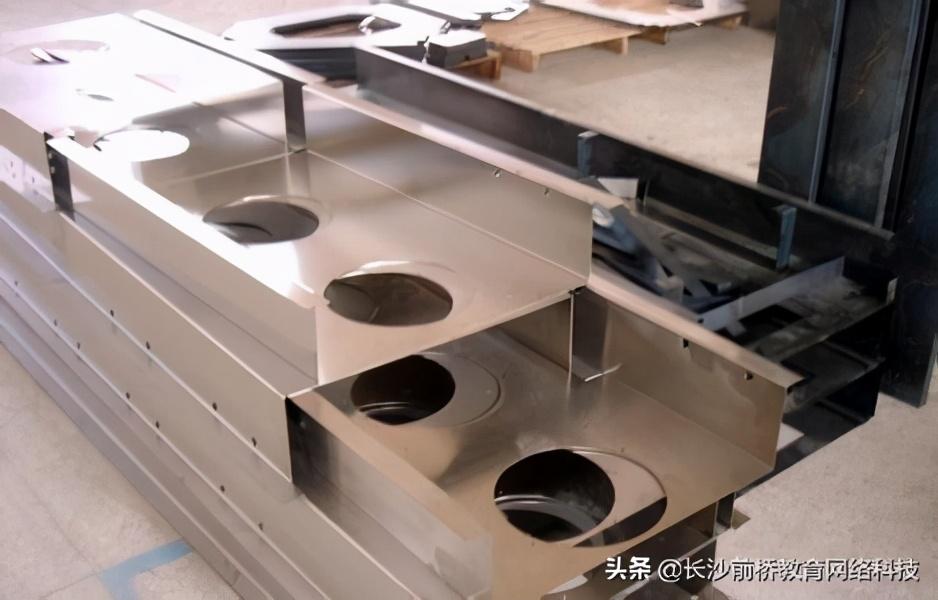

2, batch capacity

There must be a number of high-end imported processing equipment, such as CNC numerical control lathes, automatic cutting machines, small punches, general cars, general milling, etc., and an experienced team.

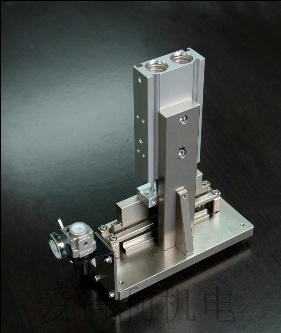

3. Quality control capabilities

The company has a testing center and a comprehensive range of high-end testing equipment, such as three-coordinate measuring machines, two-dimensional, two-dimensional altimeters, push-pull testers, hardness testers, roughness testers, salt spray testers, etc. The rigorous quality control process can meet the stability and reliability requirements of medical, automotive, communications, optoelectronics and other industries.

4. Technical service capabilities

It is necessary to have an excellent team of engineers who can provide on-site technical support and first-hand feedback to the customer‘s R & D personnel during the pre-stage, sample trial production stage and mass production stage of the customer‘s new Product Research & Development. At the same time, always pay attention to the problems and new requirements of the customer in the cooperation, and use this as an opportunity to improve the products and services provided.

Precision mold parts processing manufacturers want to develop in the market and have stronger market competitiveness, they need to have certain advantages in many aspects. Changsha Borun Mould Co., Ltd. is an enterprise specializing in the processing of precision mold parts. The company introduces overseas advanced design concepts and manufacturing technologies, integrates new technologies, integrates upstream and downstream resources in multiple industrial fields, and forms a whole supply chain service from design to manufacturing.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole