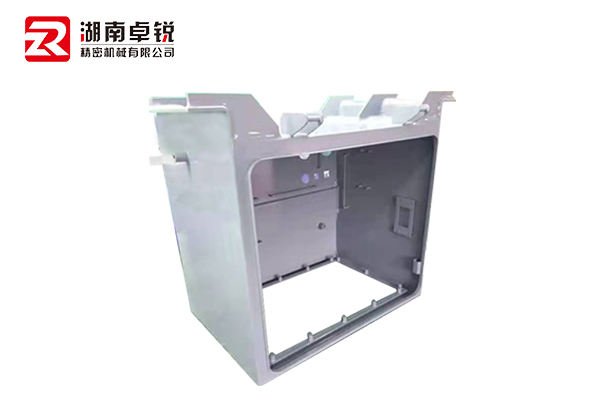

At present, in the processing industry, sheet metal chassis processing has become a more prominent form of processing in the processing industry. This is mainly because the products processed by sheet metal chassis are not only beautiful in appearance, but also durable and long in service life, so they are deeply favored and loved by all walks of life. However, if we want to obtain a sheet metal chassis processing part that meets the quality standards, there are many aspects in the process of sheet metal shell processing that require our attention.

Chassis cabinet Sheet Metal Processing cabinet quality is of course important, but its accessories must not be ignored. It is very important to choose suitable high-quality accessories for the normal operation of the cabinet chassis. Which parts need our attention for cabinet chassis sheet metal processing?

First, the backplane:

The backplane is a very important accessory in the sheet metal processing of the chassis and cabinet. It is mainly used to place PLCs, power supplies, relays, fuses, terminals and other devices. The existence of the backplane of the chassis ensures the transportation and normal operation of the chassis. At the same time, it is also convenient for wiring. Before placing devices on the backplane, holes need to be drilled on the backplane first. The PLC or power supply can be directly connected to the backplane, and other equipment bases are fixed on the backplane rails, and then the devices are clamped to the rails.

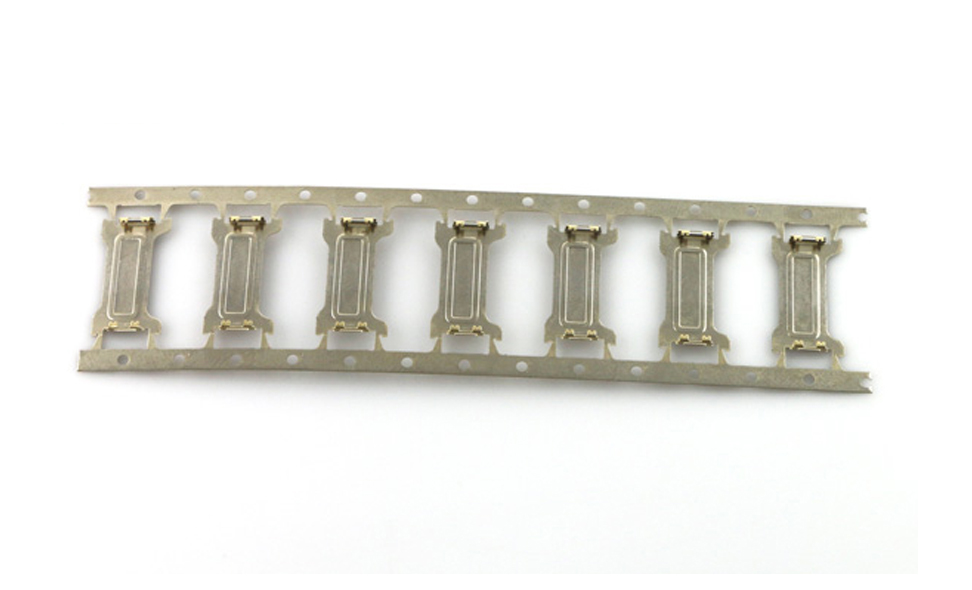

Second, dust net:

The dust net is another important accessory for the sheet metal processing of the chassis cabinet. It is a filter screen that traps dust, which can effectively prevent dust and wind and sand from entering the interior of the cabinet chassis. The dust net is usually installed at the trend of the cabinet chassis. Its outer frame is made of exquisite aluminum frame or stainless steel frame material. The inner filter plate can be made according to the needs of customers. The combination inner frame is pressed and described to ensure the tightness of the filter air and prevent dust leakage. The dust net is fireproof and moisture-proof, with low resistance, good ventilation effect, large dust capacity and high dust removal rate.

Each part of the cabinet chassis sheet metal processing plays its own role, so the parts of the cabinet chassis must not be ignored, because its good or bad directly affects the overall operating power of the cabinet chassis.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole