Numerical control processing is an important symbol to measure a country‘s economic strength, comprehensive national strength and national status, and it is also an important reason why the West has blocked our country for a long time. Because numerical control processing is too important, it is the mother base of the entire industry. The state attaches great importance to it and has always given support. In fact, in intelligent manufacturing, not only the industry but also the academic community supports it. For example, the Foundation Committee and the Chinese Academy of Sciences released the mathematics part of China‘s science strategy for the next ten years, which talked about the key mathematical problems in the transformation and renewal of traditional pillar industries.

The most important mission of numerical control machine tools is complex surface machining, because complex surfaces involve many of the most critical components in the industrial industry. Complex curved parts have the characteristics of complex surfaces, high aerodynamic performance requirements, and difficult machining path design. Generally speaking, parts like this are completed by numerical control machining methods.

In order to produce some subversive theories or transformative technologies in numerical control machining, traceability is the most important thing. Modern numerical control machining processes numerical control surfaces. Although the numerical control machine tools that people see are processed very quickly, after the action is decomposed, the surface of industrial parts can be regarded as a mathematical geometric surface, which can be processed by the method of difference according to the accuracy.

In order to produce some subversive theories or transformative technologies in numerical control machining, traceability is the most important thing. Modern numerical control machining processes numerical control surfaces. Although the numerical control machine tools that people see are processed very quickly, after the action is decomposed, the surface of industrial parts can be regarded as a mathematical geometric surface, which can be processed by the method of difference according to the accuracy.

Can you do something radical at the root, which is basically, can you do it not based on its geometry, but based on its physics?

The idea is, what is the purpose of processing a curved surface? For example, to make an engine or a propeller, the curved surface can satisfy its physical characteristics after making it, so that its efficiency can be improved. Then our basic idea is to combine the physical characteristics contained in the machined surface with the curved surface, hoping that it will have good mechanical fluidity after processing. When processing, simply do it directly according to the factory requirements, because after doing it, there is the concept of streamline.

This idea is easy to say, but it is very difficult to express mathematically and physically, and it took us three or four years to figure it out. Basically, we wanted to develop a mathematical theory that would generate transformative technology from the theory, which would make numerical control machining a one-step processing, unlike the existing two-step processing. There are two possible ways to generate streamlines, one is to do it according to the mathematical physics method, and the other is to do it according to the sample method, according to the vector method to "flow" the flow.

This idea is easy to say, but it is very difficult to express mathematically and physically, and it took us three or four years to figure it out. Basically, we wanted to develop a mathematical theory that would generate transformative technology from the theory, which would make numerical control machining a one-step processing, unlike the existing two-step processing. There are two possible ways to generate streamlines, one is to do it according to the mathematical physics method, and the other is to do it according to the sample method, according to the vector method to "flow" the flow.

Compared with the traditional numerical control methods in the past, the past machining methods were all local processing methods based on the geometric characteristics of the surface, and the overall view of the machined surface could not be seen, so the physical characteristics given by the parts produced by the surface were rarely considered. Now, based on the surface, the method we propose should not only consider the geometric shape of the surface, but also consider the information of the surrounding physical field together as a whole. In this case, its scientific processing method has undergone great changes at once, improving the functional effects of the workpiece.

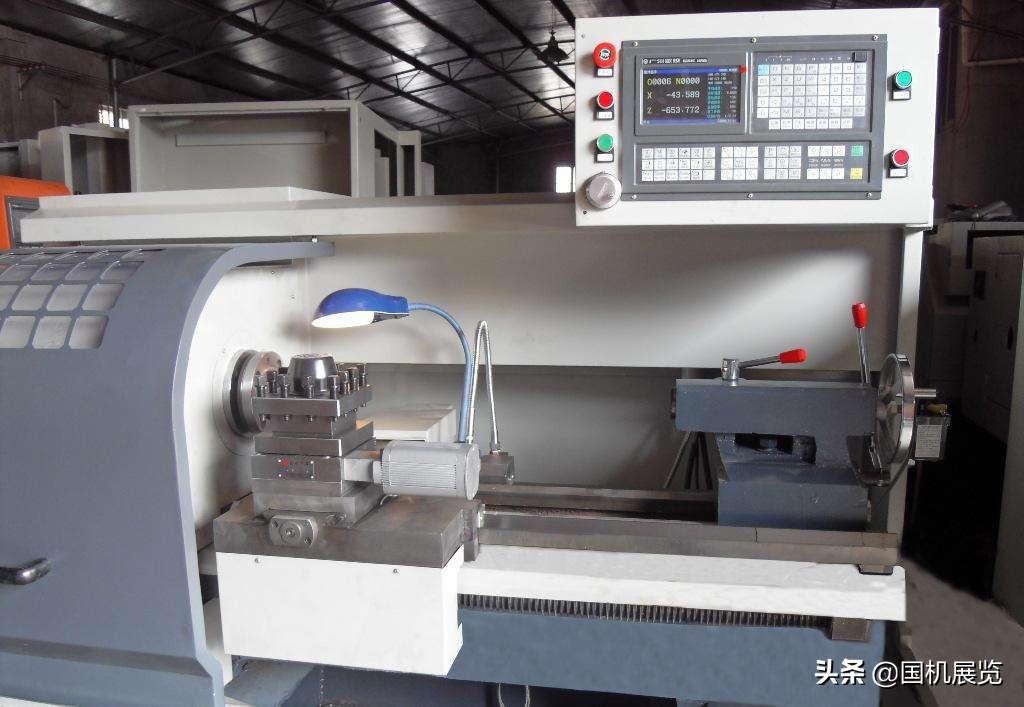

We hope to make a new type of numerical control system that can be integrated with the original and existing systems to make better contributions to the field of intelligent manufacturing in our country.

The author of this article is an academician of the Chinese Academy of Sciences, and Shenzhen EMAR Precision Technology shares a new processing concept with you.

EMAR precision technology focuses on market demand, closely follows the user‘s processing process, and introduces fully automatic numerical control centering machine, cutting machine, turning and milling composite machining center and cnc four-axis and five-axis linkage machining center. Based on medical, optical and communication precision parts, it develops customization and mass production of precision parts for automobiles, drones, intelligent machines and office automation. The company successfully passed the IATD16949 quality certification management in the automotive industry in 2008 and successfully entered the ranks of auto parts processing. It is a rare strength manufacturer with auto parts processing qualifications in Shenzhen and even Guangdong. Perfect product solutions and rigorous production processes have won the quality supplier award from medical, and communication equipment manufacturers many times.

EMAR precision technology focuses on market demand, closely follows the user‘s processing process, and introduces fully automatic numerical control centering machine, cutting machine, turning and milling composite machining center and cnc four-axis and five-axis linkage machining center. Based on medical, optical and communication precision parts, it develops customization and mass production of precision parts for automobiles, drones, intelligent machines and office automation. The company successfully passed the IATD16949 quality certification management in the automotive industry in 2008 and successfully entered the ranks of auto parts processing. It is a rare strength manufacturer with auto parts processing qualifications in Shenzhen and even Guangdong. Perfect product solutions and rigorous production processes have won the quality supplier award from medical, and communication equipment manufacturers many times.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole