What is the function of precision machining?

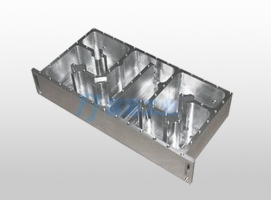

The function of precision machining The precision machining center is a high-efficiency and high-precision numerical control machine tool. The workpiece can be processed in multiple processes in one clamping, and there is also a tool library, and there is an automatic tool change function. The precision machining center can realize three-axis or more linkage control to ensure that the tool is processed on complex surfaces. In addition to linear interpolation and arc interpolation functions, the precision machining center also has various processing fixed cycles, automatic compensation of tool radius, automatic compensation of tool length, graphic display of machining process, man-machine dialogue, automatic fault diagnosis, offline programming and other functions.

The role of precision machining Precision machining centers are developed from numerical control milling machines. The biggest difference from numerical control milling machines is that the machining center has the ability to automatically exchange machining tools. By installing tools for different purposes on the tool magazine, the machining tools on the spindle can be changed through the automatic tool changing device in one clamping to achieve a variety of machining functions.

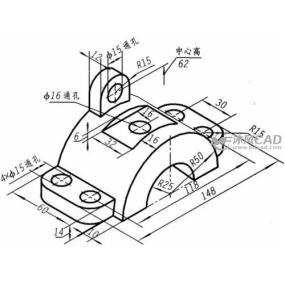

Precision machining equipment is suitable for large-scale, high-precision, and complex machining, especially for the processing of arcs, tapers, and so on.

The role of precision machining in industrial production involves issues such as materials, processes, costs, and usage quantities. Many parts cannot be mass-produced by machines, so small-scale or small-scale precision machining needs to be carried out through some special processes, and manual processing may also be involved in the middle. Generally, CNC, rapid mold, vacuum silicone compound mold and other processes are mainly used to achieve small batch production.

The role of precision machining is small. Precision machining ranges from single digits to three digits. It is processed by simple molds, soft molds, or directly. Small precision machining is generally the usual machining process such as turning, milling, planing, grinding, and pliers, and the fitter‘s cutting, drawing, punching, and tapping. Representative industries include aviation, aerospace industry, shipbuilding industry, construction machinery industry, and machine tool industry. The typical representative of mass production is the automobile industry, while the trial production of new models and engines in the automobile industry and the mold industry that mainly serves mass production still belong to a single small batch production.

The role of precision machining Small batch production can save time and material costs and speed up the product launch cycle. Small batch production is inseparable from the prototype model, which is the premise of small precision machining, and small precision machining is based on the prototype model.

The role of precision machining focuses on small precision machining, which can largely meet more personalized product customization. The progress of social civilization and the improvement of people‘s daily living standards have gradually surfaced in the pursuit of personalized materials. Personalized life and personalized products can better reflect the colorful rhythm of life. It just so happens that in industry, small precision machining uses CNC, milling machines, lathes and other industrial techniques to realize personalized products more deeply and accurately. In industrial processing, it is also faster and higher quality to meet the needs of our customers.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole