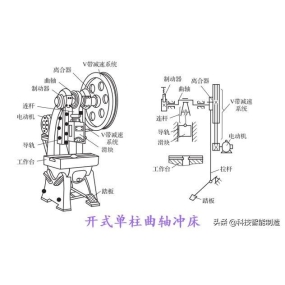

The reasons why the stamping parts are not flat and the concave arc surface appears during the precision stamping process are mainly as follows:

1. In general stamping, when the blank is initially pressed by the punch, elastic warping will occur, and a concave arc surface will be generated under the punch. If the gap is moderate and the shearing is carried out in time, the elastic warping will be eliminated fundamentally. When the gap is too large, the blank is seriously tortuous and stretched at the edge, and the shearing is delayed. The warping cannot be eliminated and remains on the stamping part as a concave arc surface. When the intermembrane is too small, because the size of the stamping part falling into the concave hole is slightly larger than the size of the hole, the workpiece is squeezed and warped, forming a concave arc surface.

The method of eliminating is to set a blank holder device (such as an elastic discharge plate) and an elastic jacking device on the precision stamping die to suppress elastic warping. When the gap is small, dressing the stamping gap can eliminate the concave arc surface of the workpiece.

2. The straight wall section of the die hole has a reverse taper or a small touch area between the top plate and the workpiece, resulting in a concave arc surface for the workpiece.

The elimination method is to repair the reverse taper of the die wall and replace the top plate.

3. When the shape of a precision stamping workpiece is complex, the uneven stamping pressure around the workpiece results in uneven warping of the workpiece.

The elimination method is to increase the blank holder force.

4. When there is oil, air or debris between the die and the stamping part, it will also cause the stamping part to flex, especially for thin and soft workpieces.

The way to eliminate it is to pay attention to strengthening the cleaning operation and plan the exhaust hole on the die when there is air.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque