Precautions for maintenance of CNC lathes

CNC numerical control machine tool refers to an automated machine tool equipped with a program control system. The control system can logically process and decode programs with control codes or other symbolic instructions, so that the machine can move and process parts. CNC machine tools are also called numerical control machine tools, numerical control lathes, etc. In our country, Hong Kong and Guangdong Pearl River Delta are directly called computer gongs.

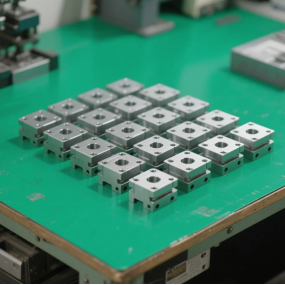

Compared with ordinary machine tools, numerical control machine tools have high machining accuracy and stable quality; and can perform multi-coordinate linkage to process parts with complex shapes; when machining parts, only need to change the numerical control program to work, which greatly saves production preparation time; at the same time, the CNC machine tool itself has high precision and rigidity, and can choose favorable processing dosage, high productivity; and for operators, the CNC machine tool has a high degree of automation, which also greatly reduces the intensity of labor; However, because of the professionalism of the program control system, the quality requirements for operation and maintenance personnel are relatively high. The maintenance of CNC machine tools is more professional and meticulous than that of ordinary machine tools. Maintenance personnel must not only have knowledge of machinery, processing technology and hydraulic pressure, but also have knowledge of electronic computers, automatic control, drive and measurement technology. Only in this way can they fully understand and master the numerical control lathe and do a good job of maintenance in time.

Maintenance mainly pays attention to 3 points:

1. Optimize the processing and production environment. The specific environment of the use of numerical control lathes will affect the normal operation of the machine tool, so the installation and use of the machine tool should try to meet the specified installation conditions to meet the environmental needs of the machine tool production. When economic conditions permit, it is best to isolate the numerical control lathe from ordinary machining equipment to facilitate the maintenance and maintenance of the machine tool. At the same time, regularly clean the factory, clean the electrical cabinets, circuit boards, etc.

2. Cultivate professional machine tool maintenance personnel. These personnel should be familiar with the mechanical, numerical control system, strong electric equipment, hydraulic, pneumatic and other characteristics of the machine tool used, as well as the use environment and processing conditions, and be able to use the numerical control lathe correctly according to the requirements of the machine tool and system instruction manual.

3. For machine tools using CMOS components, when a low voltage alarm occurs, the battery must be replaced in time, and the control system must be powered on, otherwise the storage parameters will be lost, resulting in the failure of the numerical control system.

For long-term idle numerical control machine tools, when idle, the numerical control system should also be powered on frequently and run in no-load state. In humid areas or rainy seasons, it should be powered on every day, and the electrical components themselves are used to heat up and drive away the moisture in the numerical control cabinet, so as to ensure the stable and reliable performance of electronic components.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque