With the rapid development of artificial intelligence (AI), intelligent machines have become a blue ocean field, and many manufacturers have joined the ranks of R & D and design robots, such as Google, Baidu, etc. Every intelligent machine is expensive, especially in the R & D and design stage, which requires a lot of manpower and financial resources. When it comes to mass production, there will generally be die-casting modeling, and precision machining processing.

Generally, when the sample production is completed, assembly and debugging are OK, it will be accompanied by the batch advantages of the finished product, because the requirements of intelligent machines are higher than those of traditional products. Therefore, precision machining cannot be ignored, and a whole rigorous production process chain is required. Shenzhen EMAR Precision Technology is such a manufacturer with a variety of precision machining technologies and processing strength.

We have 18 years of experience in high-precision CNC Machining, and have also participated in the customization and mass manufacturing of precision products such as medical accessories, optical accessories, and communication accessories. We have accumulated considerable experience. When it comes to the processing of robot precision parts, our general approach can be roughly divided into the following points:

When users send 3D drawings, they must first take good confidentiality measures, change the product number, and strictly protect the user‘s confidentiality, so as to minimize the possibility of revealing secrets.

2. Analyze the product process through the materials required for the product, the shape of the robot parts, and the core technical parameters, and then make a quotation form and deliver it to the user for approval.

3. Confirm the process and communicate effectively with the customer‘s engineers until the product solution is determined.

4. Through the company‘s management system, the parts processing order is sent to the production system, and then the relevant departments are organized to program to obtain the three-dimensional processing effect of the product.

5. Purchase the raw materials required for the processing of robot parts, analyze the material elements, and store the materials.

6. Conduct small-scale production and process optimization, and then produce large quantities.

7. Follow-up processing is closer, such as whether surface grinding, polishing, spraying, electroplating, silk screen printing, etc. are required;

8. Deliver to users and follow up on follow-up matters.

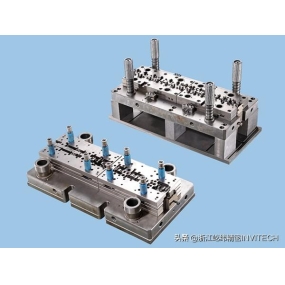

EMAR precision technology has more than 100 high-precision numerical control processing equipment such as numerical control centering machine, cutting machine, machining center, turning and milling compound machining center, which can ensure the processing of large quantities of robot precision parts and delivery on time. In order to meet the processing needs of high-precision equipment, the company specially established a precision testing center and team, with projectors, coordinate detectors, spectrometers, etc., which strictly guarantees the quality of users. Welcome to inquire, visit and discuss cooperation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque