The current application of numerical control machining has penetrated into all walks of life. The numerical control processing technology is the basis for training practical operators. In order to adapt to the needs of modern economic construction, it has cultivated talents with professional knowledge and strong hands-on ability, and can be engaged in processing tasks in production and engineering team positions.

To engage in numerical control processing, you need to master a lot of knowledge, probably as follows:

1. Mechanical drawing; 2. Metal materials and heat treatment; 3. Tolerance fit and technical measurement foundation; 4. Engineering mechanics; 5. Mechanical design foundation; 6. Machine tool fixture; 7. Hydraulic and pneumatic technology; 8. Mechanical manufacturing technology; 9. Metal cutting principles and tools; 10. Fitter skills training; 11. Electrical and electronic basic and operating skills; 12. Numerical control milling machine machining center processing technology; 13. Numerical control lathe processing technology; 14. AutoCAD, PRO/E three-dimensional modeling and design; 15. EDM technology; 16. MASTERCAM three-dimensional design and numerical control programming; 17. UG three-dimensional design and numerical control programming; 18. Numerical control machine tool structure and Maintenance;

Types of machine tools generally exposed to numerical control processing

A; according to the classification of process uses, there are mainly

Ordinary numerical control machine tools, such as numerical control milling machines, numerical control lathes, numerical control drilling machines, numerical control grinding machines, gear processing machines

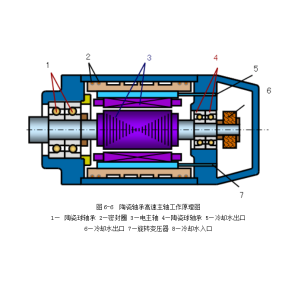

CNC Machining center, which is a high-precision machine tool that combines numerical control milling machine, numerical control bed and numerical control drilling machine.

B: According to the type of exercise

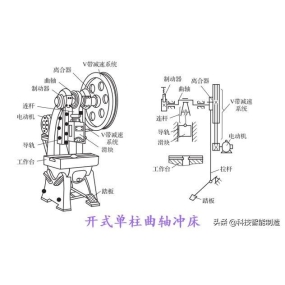

Point control numerical control machine: such as CNC drilling machine, numerical control coordinate bed, numerical control punch;

Linear control numerical control machine: common CNC milling machine, numerical control lathe, numerical control grinder;

According to the contour control mode of machine tools: common CNC lathes, numerical control milling machines, numerical control cutting machines, machining centers, etc.

C: Classify according to the control method

There are mainly open-loop control numerical control machine tools, closed-loop control machine tools and semi-closed-loop control machine tools

The employment direction of numerical control processing technology basically revolves around the design, production management and numerical control programming and processing operation of mechanical products. The specific job details include machine tool equipment debugging, operation, fault diagnosis, maintenance, transformation and after-sales services.

Development prospects of numerical control processing technology

With the rapid development of society and the progress of science, the demand for professional and technical personnel in the machining profession has been constantly changing. The development of information technology, especially the wide application of CAD/CAM, has led to the rapid development of numerical control processing technology, and has also brought revolutionary changes to the traditional manufacturing industry. As a training center for talents in need, many schools have also carried out related majors to teach, and the construction of their majors must be reformed to meet the needs of society. Over the years, the demand for professional and technical personnel in the Pearl River Delta and Yangtze River Delta has been increasing, mainly reflected in machinery manufacturing, numerical control technology application, mold design, etc., and has been derived to the industry. It is manifested in aviation manufacturing and aerospace equipment. Military instruments, textiles, machinery, automobiles, optics, etc., in the machinery manufacturing industry, more than 90% of the industries need to use numerical control machine tools.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque