Precision parts machining: numerical control machining surface roughness and its three influencing factors

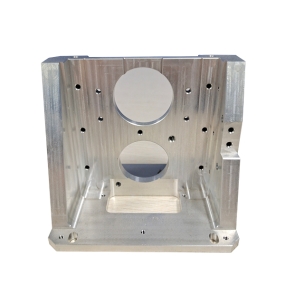

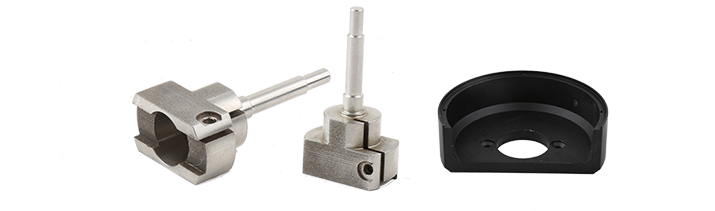

The geometric characteristics of the machined surface by numerical control include surface roughness, surface waviness and surface processing texture. Surface roughness is the basic unit that constitutes the geometric characteristics of the machined surface. When machining the surface of a workpiece with a metal cutting tool, the surface roughness is mainly affected by three aspects: geometric factors, physical factors and numerical control machining process factors.

(1) Geometric factors

(1) Geometric factors

From a geometric point of view, the shape and geometric angle of the tool, especially the tip arc radius, main declination angle, auxiliary declination angle and the feed amount in the cutting dosage, have a great influence on the surface roughness.

(2) Physical factors

Considering the physical essence of the cutting process, the rounded edge of the cutting tool and the extrusion and friction behind it cause plastic deformation of the metal material, which seriously deteriorates the surface roughness. When the plastic material is processed by the numerical control lathe to form banded chips, it is easy to form a chip accumulation tumor with high hardness on the front tool face. It can replace the front tool face and cutting edge for cutting, so that the geometric angle of the tool and the amount of the back knife are changed. The contour of the chip accumulation tumor is very irregular, so that there are knife marks that change in depth and width on the surface of the workpiece. Some chip accumulation tumors are embedded in the surface of the workpiece, which increases the surface roughness. The vibration during cutting process increases the value of the surface roughness parameter of the workpiece.

(3) Process factors

From the perspective of technology, consider its influence on the surface roughness of metal parts machining, mainly including factors related to cutting tools, factors related to workpiece material and factors related to numerical control processing conditions

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque