Analysis of Process Processing Stage in CNC Machining

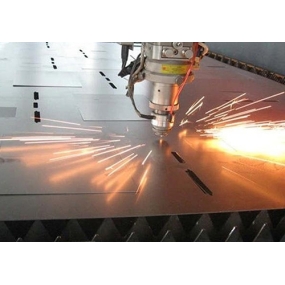

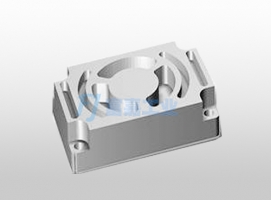

As an advanced machining method, CNC machining is widely used in the processing and production of high-precision and complex parts in the aviation industry, shipbuilding industry, and electronics industry. In CNC machining, from part drawings to machining qualified parts, it is a complex and rigorous process. If there is a problem in a certain link at each stage, the machining process will be interrupted. The following is divided into 3 stages with specific machining examples to analyze some key factors in the numerical control machining process, so that we can deepen our understanding of CNC machining and help with processing and production.

Process processing stage

Most of the numerical control machine tools used in general do not have the ability to process. The purpose of CNC machining process processing is similar to that of ordinary machine tools. However, because every detail of the numerical control machine tool processing process must be determined in advance, the processing is completed automatically. Therefore, compared with the process preparation of ordinary machine tools, it has its own characteristics.

1.1 Tool setting and tool change

When machining parts with ordinary machine tools, the positional relationship between the tool and the workpiece is established by the cooperation between the measuring tool and the handwheel. If the tool position is incorrect, it can be adjusted by the operator at any time. And numerical control processing, a clamping, there are many tools involved in the processing, in order to establish the parameters of each tool type and other input into the computer, the computer uses coordinate transformation to establish a corresponding relationship between each tool and the workpiece. For ordinary machining, the problem of tool setting is not considered as an important factor. For controlled numerical machining, as long as the program is used, the tool must be aligned, otherwise serious consequences will occur. Ordinary machining tool change is often controlled by operating feeling, while numerical control processing must carefully consider the tool change position to prevent collisions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque