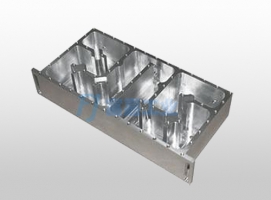

The differences between Shenzhen machining aluminum and die-casting aluminum:

Today, the editor of Fujia Industry will tell you the difference between Shenzhen machining aluminum and die-casting aluminum. Friends who need aluminum parts and other hardware products processing are welcome to inquire and discuss in detail!

The heat dissipation and good appearance properties of aluminum alloys have surpassed current plastic materials, and the weight brought by their own weight cannot be replaced by plastics.

1. Differences in materials:

Die-casting aluminum alloys generally use ADC12 or ALsi9cu3. Two-car aluminum generally uses 6063 or 6061.

2. Differences in appearance:

Die-casting aluminum is equivalent to the injection molding process of plastic, which can be made into any shape. The shell above the street lamp is generally made of die-casting aluminum. The shape of the equal cross-section used in the two car aluminum has little change, such as the heat sink of the bulb lamp and the aluminum profile of the door and window.

3. Thermal conductivity:

The general conductivity of die-casting aluminum is about 80-90W/M. K, while the thermal conductivity of car aluminum is about 180-190W/M. K.

4. Cost:

The cost of die casting and car aluminum is relatively speaking, and it is calculated by weight and machining. According to real-time material prices and labor costs. Relatively speaking, the cost of die casting aluminum is higher, but the specific situation needs to be analyzed.

5. Production efficiency:

The production efficiency of injection molding is definitely higher, mass production, generally more than 1,000 are produced a day, and the size is stable, and the shrinkage rate is 0.5%.

6. Application:

Die-cast aluminum is generally widely used in the automotive, street lamp, and now mobile phone industries. Car aluminum is widely used in downlights, ceiling lamps, doors and windows, etc.

How much have you learned about the difference between machined aluminum and die-casting aluminum? If you are not clear, you can call to communicate?

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque