Abstract:

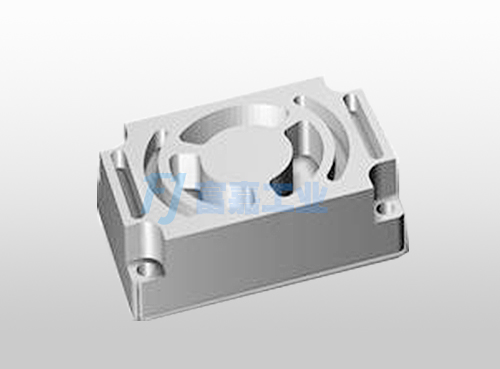

What is precision metal machining parts processing, according to the literal meaning of the words: is very precise machining, precision machining is a kind of machining, but it is in the processing of higher error requirements, and in the processing technology requirements are more stringent, with the development of modern industry and the continuous change of demand, precision machining has been a multi-faceted development, its development direction is more and more broad, the direction is more and more fine, the direction of development is more and more showing its specialization, with the development of science and technology, its technology is constantly improving, the quality and precision of processing is also getting higher and higher. The development of science and technology and economy has also firmly grasped the direction of the development of precision machining.

With the development of the machinery industry, new design theories and methods, new materials and new processes have emerged, and mechanical parts have entered a new stage of development. Theories such as finite element method, fracture mechanics, elastic hydrodynamic lubrication, optimization design, reliability design, Computer-Aided Design, entity modeling, system analysis and design methodology have been gradually used in the research and design of mechanical parts.

With the development of the machinery industry, new design theories and methods, new materials and new processes have emerged, and mechanical parts have entered a new stage of development. Theories such as finite element method, fracture mechanics, elastic hydrodynamic lubrication, optimization design, reliability design, Computer-Aided Design, entity modeling, system analysis and design methodology have been gradually used in the research and design of mechanical parts.

Therefore, in the future, precision machining will only become more and more integrated. It is no longer just a simple machining model. It is now seamlessly integrated with high-tech, but it can better play its role. In particular, the digitalization of the machining industry has made a qualitative leap in its development and can better serve industrial development.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole