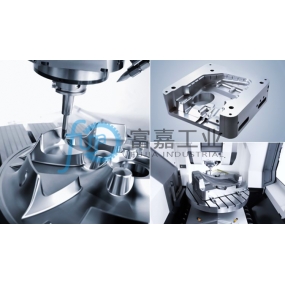

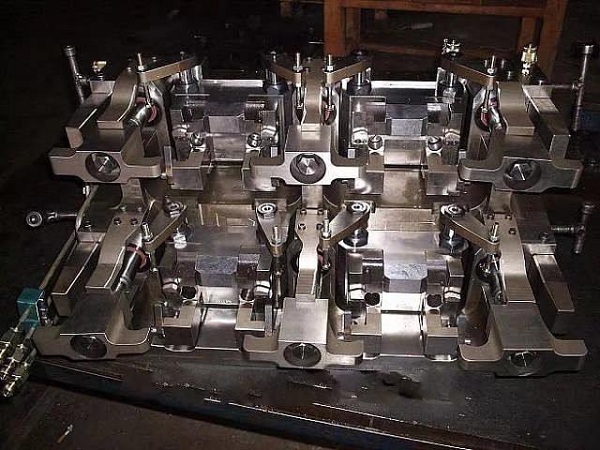

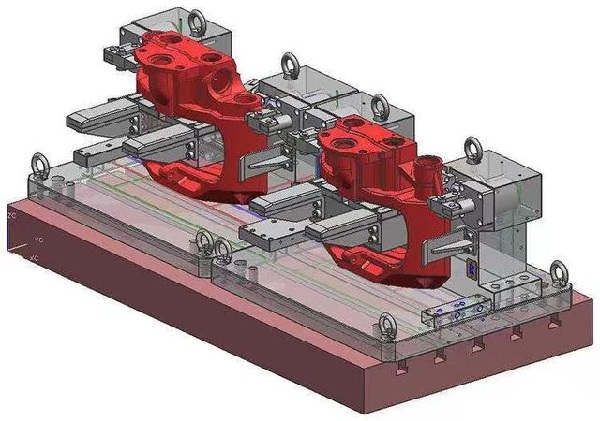

How to look at the technical level of a numerical control machine tool, the most intuitive feedback is its processing efficiency and repeated positioning accuracy, the repeated positioning accuracy of a machine tool is assumed to be able to achieve the 0.005mm standard, then this is a high-precision machine tool, but if the implementation of 0.005mm or less, that is ultra-high precision machine tool, machine tool accuracy in addition to the system, hardware also needs to have the best screw and bearing to match.

When it comes to the "accuracy" of numerical control machine tools, it is necessary to clarify the definition of standards, indicators and calculation methods. When some numerical control machine tool manufacturers in Japan calibrate "accuracy", they usually use JISB6201 or JISB6336 or JISB6338 standards. JISB6201 is generally used for general-purpose machine tools and ordinary numerical control machine tools, JISB6336 is generally used for machining centers, and JISB6338 is generally used for vertical machining centers. The three standards mentioned above are basically the same when defining positional accuracy. We use JISB6336 as an example because on the one hand this standard is relatively new, and on the other hand it is slightly more accurate than the other two standards.

When it comes to the "accuracy" of numerical control machine tools, it is necessary to clarify the definition of standards, indicators and calculation methods. When some numerical control machine tool manufacturers in Japan calibrate "accuracy", they usually use JISB6201 or JISB6336 or JISB6338 standards. JISB6201 is generally used for general-purpose machine tools and ordinary numerical control machine tools, JISB6336 is generally used for machining centers, and JISB6338 is generally used for vertical machining centers. The three standards mentioned above are basically the same when defining positional accuracy. We use JISB6336 as an example because on the one hand this standard is relatively new, and on the other hand it is slightly more accurate than the other two standards.

European machine tool manufacturers, especially those in Germany and Switzerland, generally use the VDI/DGQ3441 standard. American machine tool manufacturers usually use the NMTBA (NationalMachineToolBuilder‘s Assn) standard (which originated from a study by the American Machine Tool Manufacturers Association and was promulgated in 1968 and later revised).

The standards mentioned above are all related to ISO standards. For example, the dimensional accuracy and shape accuracy of typical parts machined by machining centers are compared at home and abroad. The domestic level is roughly 0.008~ 0.010mm, while the international advanced level is 0.002~ 0.003mm.

The standards mentioned above are all related to ISO standards. For example, the dimensional accuracy and shape accuracy of typical parts machined by machining centers are compared at home and abroad. The domestic level is roughly 0.008~ 0.010mm, while the international advanced level is 0.002~ 0.003mm.

Although the development of our country‘s machine tool manufacturing industry has ups and downs, but the numerical control technology and numerical control machine tools have been given greater attention, has a strong market competitiveness. However, in the middle and high-grade numerical control machine tools, with some foreign advanced products and technology development, there is still a big gap, most of them are in the technical tracking stage.

Ultra-precision machining currently refers to the size and position accuracy of 0.01~ 0.3μm, shape and contour accuracy of 0.003~ 0.1μm, surface roughness of steel Ra0.05μm, copper Ra0.01μm. The ultra-precision numerical control lathe and numerical control milling machine developed in China have been put into production. At present, it is necessary to develop ultra-precision grinding machines and ultra-precision composite machining machine tools in terms of varieties. At the same time, it is necessary to further improve the performance of ultra-precision spindle unit, ultra-precision guide rail sub-unit, ultra-precision smooth drive system, ultra-precision contour control technology and nano-resolution numerical control system and accelerate its engineering.

Ultra-precision machine tools are mainly used to solve the ultra-precision machining of domestic high-tech and national defense key products. Although the demand is not very large, it is a sensitive technology blocked by foreign technology. On the other hand, the deepening research of ultra-precision machining technology will help the development and industrialization of high-precision machine tools that require a large amount of machining accuracy at the sub-micron level.

Ultra-precision machine tools are mainly used to solve the ultra-precision machining of domestic high-tech and national defense key products. Although the demand is not very large, it is a sensitive technology blocked by foreign technology. On the other hand, the deepening research of ultra-precision machining technology will help the development and industrialization of high-precision machine tools that require a large amount of machining accuracy at the sub-micron level.

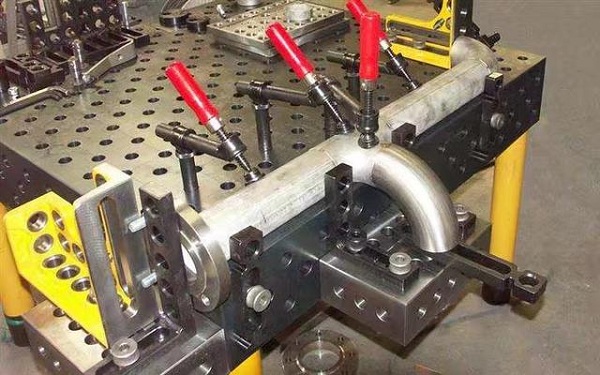

Shenzhen EMAR Precision Technology Co., Ltd. is a professional dedicated to high-precision numerical control machine tool external processing strength manufacturers, the company has more than 100 high-precision numerical control machine tools, can provide lathes, milling machines, drilling machines, composite processing, cnc processing business, products cover medical, communications, optics, drones, robots, automobiles, office automation, the company successfully passed the IATF16949 quality management certification last year, in the realization of high-efficiency processing while the product accuracy control within 0.01mm.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque