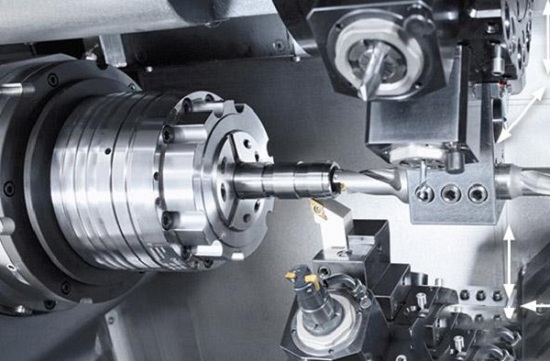

Shenzhen EMAR precision technology is a professional committed to high-quality CNC processing strength manufacturers, the company has passed ISO9001, ISO14001, IATF16949 and high-tech enterprise certification, we have summarized for you today numerical control machining manufacturers often use some of the industry language, may not find these content in writing, but in reality will often use, so, whether you are a user or manufacturer, or is a practitioner, you can understand, to facilitate the communication between suppliers, or customers, or colleagues, if it is just a brother into the industry, you can collect Oh.

Tract, wire, strip: 0.01 mm;

Tract, wire, strip: 0.01 mm;

One: millimeter, for example, 10 millimeters is called 10, for example: there are still 10 quantities of this part;

Pick thread, pick buckle: thread;

Set buckle, set wire: pull braces thread;

Piece a knife: car a knife;

Innerhole: roughing of the inner hole. But generally refers to the inner hole with a small diameter;

Quenching (zan): quenching;

Stuffing: tempering;

Park: shape and position accuracy is not qualified, such as uneven board, disc is not round, rotary swing, coaxiality is not good;

Chrome: pronounced "lo", chrome plated;

Tip (shao, four tones): taper, slope, refers to the workpiece with a large end and a small end;

Tip (shao, four tones): taper, slope, refers to the workpiece with a large end and a small end;

Strangle: because of extrusion deformation, the tool plastic can not be cut, generally multi-finger milling cutter;

Knife: The knife is cracked and broken;

Wai (tile) knife: the tool is inserted into the workpiece, causing the workpiece to be defective;

Purple (pronounced shai three times): The paint used by the fitter to apply the surface of the workpiece to facilitate marking;

Shell: chip breaker;

Shell opening (qiao four sound): turning tool grinding chip groove;

Lazhuang: rough processing, northeast;

Roughing: roughing, southern;

Wind mill: a rotary cutter similar to a milling cutter installed on a wind grinding wheel, for fitters;

Curved ruler: straight ruler;

Curved ruler: straight ruler;

Le: use carbide tools for high-speed finishing, because the cutting at this time is extrusion processing, so it is called le. Generally speaking, it is just a verb, and there must be an appropriate language environment before and after it. For example, this alloy tool is used for finishing.

Mill: reamer, but that seems to be less said;

Shake handle: hand crank is counted, such as handwheel;

Kilogram wrench: torque wrench;

Pliers: The meaning is broad, it depends on who to tell and understand with the other party. There are often mistakes when borrowing things. For example, pliers, pliers, as long as there are pliers, they count, but fitters do not count;

Air bag: air pressure receptacle, looks a bit like a gas tank;

Grilling the outer circle: the outer circle of the car. The outer circle of the rough car hair embryo is also called grilling the black skin;

End plane: car plane;

Barrier: Something used to fasten and card a stack of thin iron plates together. It functions like a vice and is shaped like the D word. The vertical one is a screw;

Pu (piao, two tones): the shape and position accuracy is unqualified, such as: the plate surface is uneven, the disc is not round, the rotation and swing, and the coaxiality is not good;

Pu (piao, two tones): the shape and position accuracy is unqualified, such as: the plate surface is uneven, the disc is not round, the rotation and swing, and the coaxiality is not good;

Catching up: The focus is on a‘catch ‘word. Hand-eye closed-loop servo, 2-axis linkage, two-hand stepping, "human-controlled" machine tool. Shake the handwheel with both hands to control the speed of each slide and process more complex shapes. General lathes rely on space feeling and sample, milling machines rely on lines drawn by fitters, experts can control the error within 20 lines, and powerful gold mills can even machine with 2 axes and a half;

Tap tapping wire: tap tapping thread;

Light knife: finishing tool, generally refers to the spring light knife of the lathe;

Light: to improve the surface finish for the purpose of finishing, derived with a light knife, light activity;

Light activity: finishing the surface of the workpiece to improve its finish.

Noun Explanation "light": verb. Generally refers to "fine" and "last time". For example, "light knife" refers to "fine car knife", and "light knife" refers to "fine car last knife". The scope of "light" can be too broad, "fine grinding", "fine milling", "fine car", etc., generally refers to the last time, and requires high precision. The word "light" may be derived from "surface finish". (Now changed to "surface roughness", because "finish" is literally interpreted as "the degree of light and cleanliness". According to this interpretation, "mirror" best meets the requirements and is easy to mislead.)

How about it? Did you come into contact with a lot of the above words? You still don‘t understand what it means when you first come into contact with it. A great business manager once said that in the field of communication, the shortest line between two points is not a straight line, but the line with the least obstacles. It may be an arc or an irregular shape. Machining manufacturers face users, operators, or design institutes, all of which need to be communicated many times, mainly including processing technology. Mastering the industry terminology of machining can communicate more effectively and in a timely manner, and it is necessary for manufacturers to complete user requirements more perfectly. Shenzhen EMAR Precision Technology Co., Ltd. is based on the medical, communication, optoelectronic industry, gather market demand, develop automotive, office automation product manufacturing field, keep improving, move with demand, pay attention to and close to the user process, quickly respond to user requests, so that users can focus more on their main business, enhance user value.

How about it? Did you come into contact with a lot of the above words? You still don‘t understand what it means when you first come into contact with it. A great business manager once said that in the field of communication, the shortest line between two points is not a straight line, but the line with the least obstacles. It may be an arc or an irregular shape. Machining manufacturers face users, operators, or design institutes, all of which need to be communicated many times, mainly including processing technology. Mastering the industry terminology of machining can communicate more effectively and in a timely manner, and it is necessary for manufacturers to complete user requirements more perfectly. Shenzhen EMAR Precision Technology Co., Ltd. is based on the medical, communication, optoelectronic industry, gather market demand, develop automotive, office automation product manufacturing field, keep improving, move with demand, pay attention to and close to the user process, quickly respond to user requests, so that users can focus more on their main business, enhance user value.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque