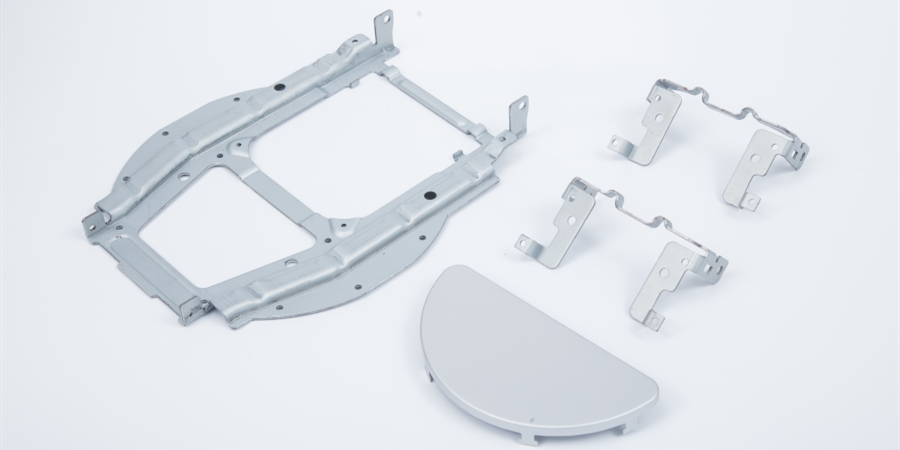

Some people always wonder what is the edge of the stamping parts in the stamping processing plant, which refers to the residual material left between the stamping parts and the side of the stamping parts and seasoning. What is the function of the edge and what aspects need to be paid attention to? Let us EMAR answer it for you. First, introduce the function of the edge:

1. It can compensate for positioning errors and cutting errors during strip feeding, ensuring that qualified parts are flushed out.

2. Maintain the rigidity of the strip, facilitate feeding, and improve labor efficiency.

3. Prevent the burrs on the edge of the seasoning from being brought into the mold gap during punching, thereby improving the life of the mold.

Secondly, the stamping parts of the stamping processing plant need to pay attention to the following aspects:

1. Mechanical properties of Metal Stamping materials. The edge value of hard materials can be smaller, and the edge value of soft materials and brittle materials should be larger;

2. The thickness of the metal stamping material, the thicker the material, the greater the edge value.

3. The shape and size of the punching parts. The more complex the shape of the part, the smaller the fillet radius, and the larger the edge value;

4. Feeding and blocking methods; when using technical feeding, the edge value of the side pressure equipment can be smaller; the edge value of the side blade spacing is smaller than the edge value of the stopper pin spacing;

5. Discharge method; the edge value of elastic discharge is smaller than that of rigid discharge.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque