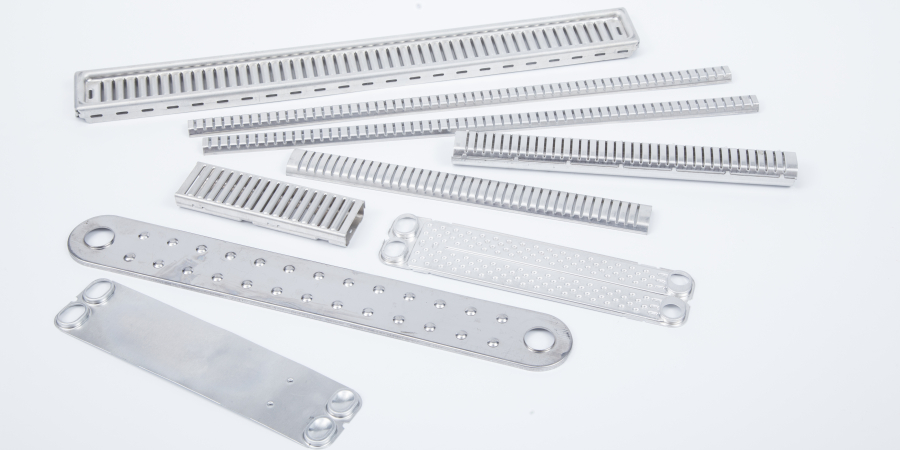

The use of Metal Stamping parts in our lives is very widespread, often involving the appearance of wear resistance, corrosion resistance functional requirements, in order to further improve the utilization rate of hardware products, it is very important to do a good job in the protection of the appearance of hardware products. Metal stamping processing of the outer surface can be subdivided into the following categories:

1. Spray paint processing: At present, many factories use spray paint processing in hardware stamping processing, such as: daily necessities, electrical enclosures, handicrafts, etc. The existence of spray paint not only makes the product less prone to rust, but also produces some other effects, making the performance of the product more outstanding;

2. Surface polishing processing: Surface polishing processing is generally used for a long time in daily necessities. By performing surface burr treatment on hardware products, the sharp corners are thrown into a smooth face, so that it will not cause damage to the human body during use;  3. Oxidation treatment: Oxidation treatment is mainly anodic oxidation, chemical oxidation, and micro-arc oxidation. Wear test and corrosion resistance test, detailed analysis and comparison of the surface tracing, oxide layer thickness, conflict resistance and corrosion resistance of aluminum alloys after three types of surface treatment. The results of surface treatment of metal stamping parts show that different thickness oxide films can be formed on the surface of aluminum alloys through different surface treatments, surface hardness and conflict resistance are significantly increased, and alloy corrosion resistance is also improved to varying degrees. Overall, micro-arc oxidation is much better than anodic oxidation, and anodic oxidation is much better than chemical oxidation.

3. Oxidation treatment: Oxidation treatment is mainly anodic oxidation, chemical oxidation, and micro-arc oxidation. Wear test and corrosion resistance test, detailed analysis and comparison of the surface tracing, oxide layer thickness, conflict resistance and corrosion resistance of aluminum alloys after three types of surface treatment. The results of surface treatment of metal stamping parts show that different thickness oxide films can be formed on the surface of aluminum alloys through different surface treatments, surface hardness and conflict resistance are significantly increased, and alloy corrosion resistance is also improved to varying degrees. Overall, micro-arc oxidation is much better than anodic oxidation, and anodic oxidation is much better than chemical oxidation.

As for how to choose the right appearance treatment? Hardware stamping processing plants should consider the material, processing technology and use of the stamping parts comprehensively, and choose the appropriate appearance treatment method for the product to make the stamping parts more beautiful and durable.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque