Do you know the characteristics of numerical control precision parts processing?

Numerical control of precision parts processing

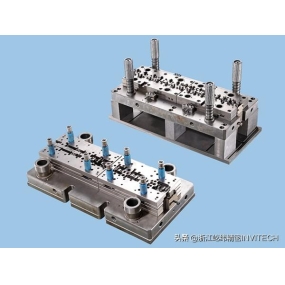

Precision parts in practical applications is necessarily the higher the accuracy, the more refined the more can reflect the processing level and quality, at the same time, such products are more popular with consumers, in general, numerical control processing in the processing has incomparable advantages and characteristics, the product quality is usually higher, so what are the characteristics of numerical control precision parts processing?

1, first of all, numerical control precision parts processing production efficiency is higher, numerical control parts processing can be processed at the same time multiple surfaces, compared to ordinary lathe processing can save a lot of processes, save time, and numerical control processing parts quality is relatively ordinary lathe to be much more stable.

1, first of all, numerical control precision parts processing production efficiency is higher, numerical control parts processing can be processed at the same time multiple surfaces, compared to ordinary lathe processing can save a lot of processes, save time, and numerical control processing parts quality is relatively ordinary lathe to be much more stable.

2, numerical control precision parts processing in the development of new products has an irreplaceable role, generally through programming can be different degrees of complexity of parts processing ah, and modification and update design only need to change the lathe program, which can greatly shorten the product development cycle.

3. The degree of automation of numerical control precision parts processing is very sufficient, which greatly reduces the physical labor intensity of workers. Workers do not need to control the whole process like ordinary lathes during processing, mainly to observe and supervise the lathe. However, the technical content of the corresponding numerical control processing is higher than that of ordinary lathes, so it requires higher mental labor than ordinary lathes.

4. The initial investment is relatively large compared to ordinary lathes, because the price of numerical control lathes is very high, and its maintenance cost and processing first preparation period are long

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque