Shenzhen EMAR precision technology is a professional dedicated to high-precision numerical control machinery external processing strength manufacturers, the processing business includes numerical control centering machine, numerical control cutting machine, turning and milling compound, CNC Machining center and other external processing, today, EMAR precision technology for you to summarize in the process of large-scale machining, we should pay attention to some safety accidents, together to see the specific content.

Numerical control machine tools in the processing process, if the operation is not careful, it may bring danger and cause accidents. In the actual operation process, many small and medium-sized enterprises ignore safety training, resulting in many tragic incidents that occur inadvertently. We need to pay attention to the following points during processing:

First of all, the pressure machinery part can lead to the existence of some dangers, such as punches, shears, crushing and abrasives, which are all pressure processing machinery. Therefore, this type of equipment requires human operation, and human operation may be caused by fatigue or emotional fluctuations. Therefore, there will be safety hazards and accidents.

Secondly, the dangerous opening rate of the transmission device during actual operation is also relatively high. The transmission parts of the machine tool are generally composed of belt or gear transmission, chain transmission, etc. These parts are generally designed with mechanical properties in mind and safety performance ignored. Many are not even designed with protective layers. What‘s more, the transmission parts are exposed, which can easily twist into people‘s hands, clothes, and hair, resulting in injuries.

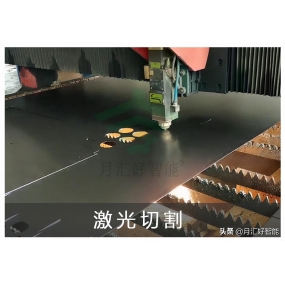

Then the machine itself caused by the injury, numerical control machining in many machine tools are used in the high-speed operation of the cutting mode, therefore, the risk factor must be caused ah attention, tool collision, iron splatter and other factors should be considered, the operator‘s improper position and other factors are easy to bring personal safety accidents.

Therefore, in the process of numerical control machining, we must pay attention to the above risk factors, and regularly carry out Security Training for employees, pre-job training is very important, to prevent fatigue, operator‘s operating position, operator‘s clothing should be paid attention to, to avoid the occurrence of safety accidents.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque