In the processing of stamped parts in stamping processing plants, the stretching process is also a treatment method that is often used. During processing, the first thing you will encounter is the stamping direction of the stretched parts. This aspect is very important, it will not only directly affect the quality of the stretched parts, but also affect some related parameters in the process.

The stamping direction of the stretched part should meet the following requirements:

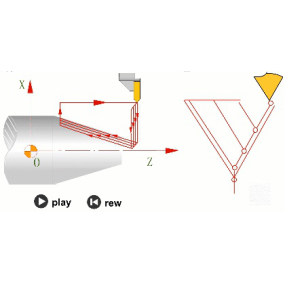

1. Ensure that the punch can enter the concave mold.

2. Make the contact area of the punch as large as possible, because this is most conducive to improving the deformation of the stretched parts.

3. The feed resistance of each part of the pressing surface should be kept uniform, which is also a strong guarantee for the quality of the stretched parts.  In the stretch forming process of stamping parts in a stamping processing plant, it is divided into one-time stretch forming and multiple-time stretch forming. The characteristic of one-time stretching is one-time molding, which can improve the production power. The disadvantage is that one-time molding is simple and not in place and can only stretch some relatively simple parts, and the degree of change of each stretch is required and cannot be changed too much.

In the stretch forming process of stamping parts in a stamping processing plant, it is divided into one-time stretch forming and multiple-time stretch forming. The characteristic of one-time stretching is one-time molding, which can improve the production power. The disadvantage is that one-time molding is simple and not in place and can only stretch some relatively simple parts, and the degree of change of each stretch is required and cannot be changed too much.

Multiple stretching can improve the pass rate of the product, and it is not easy to produce waste products. The center of multiple stretching is de-stressed and annealed and softened. Multiple stretching can ensure the accuracy of the workpiece, the elongation coefficient and the production power have been greatly improved. Multiple stretching can make the pulling more symmetrical and reduce the defective rate of the workpiece.

One-time stretching and multiple stretching have their own advantages and disadvantages. Stamping plants need to choose the stretching process according to product characteristics.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque