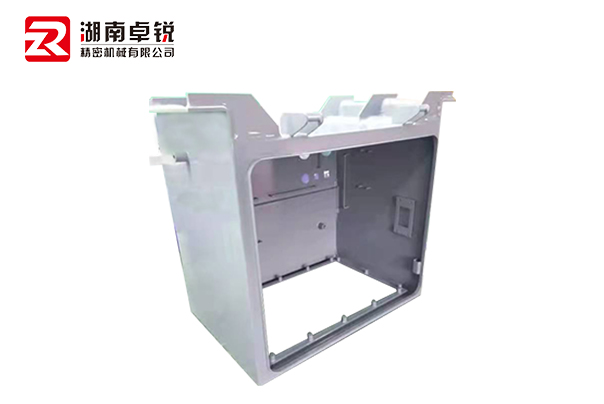

In today‘s living environment, Sheet Metal Processing of chassis and cabinets has been inseparable from us. Indeed, our daily life requires a large number of sheet metal chassis and cabinets to support. As a sheet metal processing manufacturer, how can we process high-quality sheet metal chassis and cabinets? The sheet metal chassis processing editor believes that in order to process high-quality sheet metal chassis and cabinets, we can start from the following aspects:

First, ensure the safety of sheet metal chassis cabinets during processing.

In the process of sheet metal processing of chassis and cabinet, safety is the top priority. Because safety is not only related to the overall equipment of sheet metal processing, but also an important guarantee for the personal safety of the operators. In order to ensure the safety of sheet metal processing, we can install some arrester devices, and the installation cooperation of backup equipment is also important.

Second, do a good job of chassis and cabinet guide rail processing.

1. The connection between the guide rail and the cabinet rack is usually by screwing or hanging, or welding. The guide rails are respectively welded, nephew and hanging.

2. Rigid guide rails are used in pairs, and the quality of ordinary insert boxes is less than 50 tons. Therefore, better rigidity should be considered, especially in vibration conditions. The way to increase rigidity is to increase the cross-section of the guide rails, but this will take up space in the cabinet.

3. Positioning device Sometimes connectors are required for electrical connection between the plug-in box and the cabinet. For example, positioning by the guide rail alone is often not accurate. At this time, a positioning guide pin can be installed on the plug-in box for accurate positioning.

Third, do a good job of bending the steel plate of the sheet metal chassis cabinet.

1. The bending line ZUI of the bending parts of the chassis and cabinet should be perpendicular to the direction of the rolling pattern. ZUI should use the bright surface of the blank as the surface of the bending parts to reduce the cracking of the outer layer;

2. The cross-section of the bending parts of the chassis and cabinet will change in the bending deformation zone. The smaller the ratio of the bending radius to the plate thickness, the greater the change of the cross-section shape;

3. The rebound phenomenon occurs when the sheet metal of the chassis and cabinet is bent and formed. The larger the ratio of the bending radius to the plate thickness, the greater the rebound.

Fourth, high-quality chassis cabinets must have the following characteristics:

1. Dust resistance. Long-term failure to clean up the cabinet will leave a lot of dust on the surface or inside. The accumulation of dust makes the fan inside the cabinet unable to operate normally, and also increases its noise frequency. Therefore, dust resistance is a link that users cannot ignore.

2. Heat dissipation. The good or bad heat dissipation of the chassis cabinet will directly affect its operation efficiency, and sometimes even cause paralysis to make it unable to operate. Therefore, heat dissipation can be said to be one of the main functions of the chassis cabinet ZUI.

3. Scalability. Leaving enough room for expansion inside the chassis and cabinet sheet metal processing will bring great convenience to future upgrades, and it is also convenient to protect them together.

By doing a good job in the above four aspects, you will be able to produce high-quality sheet metal chassis cabinets.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque