Sheet Metal Processing is a pivotal technology that sheet metal technicians need to grasp, and it is also an important process for forming sheet metal products. Sheet metal processing includes traditional methods and process parameters such as cutting, punching, and bending. It also includes various cold stamping die structures and process parameters, various equipment working principles and operation methods, as well as new stamping technologies and new processes. Sheet metal processing for parts is called sheet metal processing.

Sheet metal processing technology is divided into laser cutting, stamping, bending, forming, welding, polishing, spraying, printing, assembly and other processes. What industries are sheet metal processing parts used in?

Machinery industry:

Machinery industry:

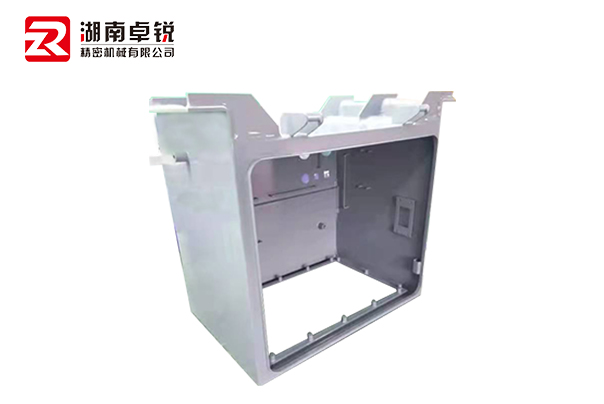

The application of mechanical equipment shells has been ubiquitous, such as power electrical cabinets, distribution cabinets, control cabinets, network cabinets, computer chassis, industrial control chassis and various sheet metal parts. Chassis cabinet sheet metal processing

Automotive industry:

Automobile doors are mainly made of cold-rolled galvanized sheet as the main material, which is formed by rolling/stamping/welding. The slide rail assembly seat slide rail is formed by high-precision stamping, welding and other processes. The sheet metal processing requirements of auto parts are relatively strict, and special project certification is required. The aluminum door frame assembly is mainly made of aluminum profiles and is stamped by sheet metal processing technology.

New energy industry:

New energy vehicles are one of the key industries supported by the state due to energy conservation and environmental protection, and there are many parts designed for sheet metal processing. Nowadays, new energy vehicle battery packs, energy storage mobile power supply shells, large energy storage inverter shells, and centralized photovoltaic equipment shells are more popular.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque