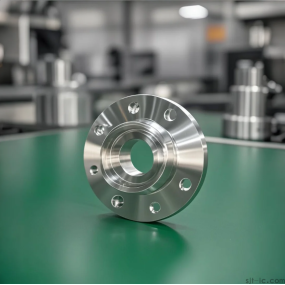

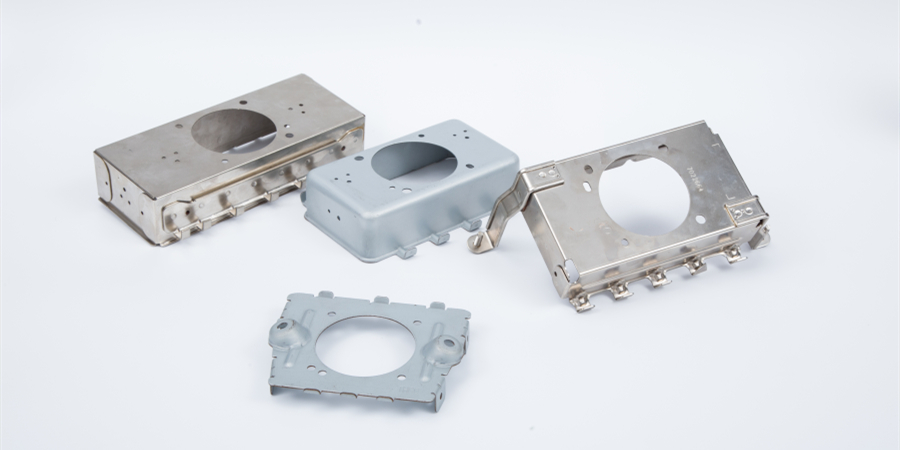

In order to consistently produce good and qualified stamping parts, precision stamping parts processing plants must protect and maintain the stamping parts of stamping parts processing equipment. Mainly include: stamping parts, feed drive organization, guide rails and other parts.

1. Good smoothing effect can reduce the working temperature of the bearing and extend the service life; for this reason, it should be noted in the operation: at low speed, choose grease and oil circulation smooth; at high speed, choose oil mist and oil and gas smoothing method. However, when selecting grease smoothing, the sealing amount of the pressure bearing is generally 10% of the bearing space volume, and the precision stamping parts processing plant must not fill it up at will, because too much grease will increase the pressure and heat generation. For smooth oil circulation, check the pressure smooth constant temperature oil tank every day during operation to see if the oil volume is sufficient. If the oil volume is not good, the smooth oil should be increased in time; at the same time, pay attention to check whether the temperature scale of the smooth oil is appropriate.  2. In order to ensure excellent smoothness in the processing of stamping parts, reduce conflict heat generation, and at the same time take away the heat of pressure components, a circulating smoothing system is generally used, a hydraulic pump is used to supply oil smoothly, and an oil temperature controller is used to control the oil temperature of the tank. High-grade numerical control punching press pressure bearings use a high-quality grease storage method to be smooth, and each addition of grease can be used for 7 to 10 years. The new smooth cooling method not only reduces the temperature rise of the bearing, but also reduces the temperature difference between the inner and outer rings of the bearing to ensure that the pressure heat deformation is small.

2. In order to ensure excellent smoothness in the processing of stamping parts, reduce conflict heat generation, and at the same time take away the heat of pressure components, a circulating smoothing system is generally used, a hydraulic pump is used to supply oil smoothly, and an oil temperature controller is used to control the oil temperature of the tank. High-grade numerical control punching press pressure bearings use a high-quality grease storage method to be smooth, and each addition of grease can be used for 7 to 10 years. The new smooth cooling method not only reduces the temperature rise of the bearing, but also reduces the temperature difference between the inner and outer rings of the bearing to ensure that the pressure heat deformation is small.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque