Preventive equipment inspection and maintenance in Shenzhen Machinery Processing Plant mainly includes the following aspects: equipment cleaning and maintenance, equipment point inspection, independent maintenance and pre-overhaul. The implementation steps are summarized as follows:

○ 1 Through the training of employees, make them familiar with the basic operation techniques of equipment maintenance and equipment use, and avoid equipment failure or damage caused by improper operation; ○ 2 Train specialized technicians to be familiar with the structure of equipment and fault diagnosis, troubleshooting and maintenance techniques; ○ 3 Collect and summarize Facility Management experience to improve the efficiency of equipment use and management.

For preventive equipment maintenance and maintenance, the purpose is to maximize the function of the equipment with the least equipment maintenance costs, so it is essentially a matter of choosing the best maintenance cost and cost-effectiveness. This is not only a management issue, but also an optimization problem. This problem is more concentrated in the maintenance of equipment and the scheduling of maintenance plans.

For preventive equipment maintenance and maintenance, the purpose is to maximize the function of the equipment with the least equipment maintenance costs, so it is essentially a matter of choosing the best maintenance cost and cost-effectiveness. This is not only a management issue, but also an optimization problem. This problem is more concentrated in the maintenance of equipment and the scheduling of maintenance plans.

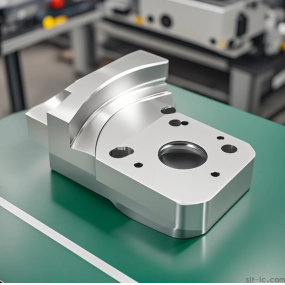

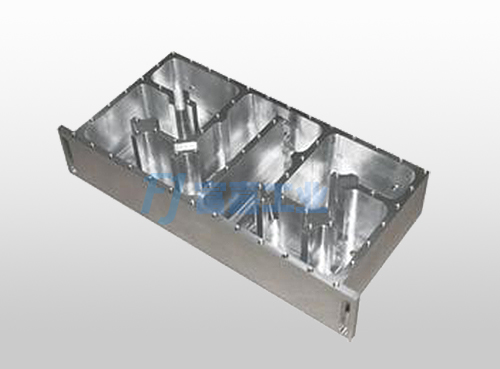

During the use of equipment in Shenzhen machinery processing plants, they are affected by factors such as temperature, humidity, continuous operation time, service life of the equipment, and material of the equipment. This requires maintenance personnel to analyze the health status of the equipment operation through the actual use of the machinery and equipment, so as to formulate a reasonable plan for the daily maintenance and downtime of the equipment in a timely manner. The effect of this should be to avoid unnecessary downtime first, and secondly to achieve daily maintenance of the equipment without affecting the normal operation of the equipment as much as possible, and to deal with any abnormal situations found in a timely manner.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque