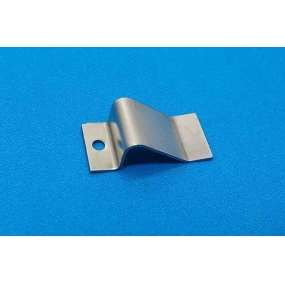

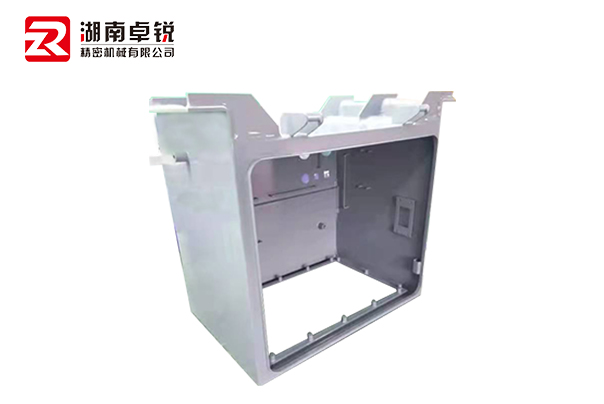

Sheet Metal Processing is called sheet metal processing. For example, the use of sheet metal to make chimneys, iron drums, fuel tanks, oil pots, ventilation pipes, elbows, round places, funnels, etc. The main processes include shearing, bending, buckling, bending, welding, riveting, etc., which require certain geometric knowledge. Sheet metal parts are thin plate hardware parts, that is, parts that can be processed by stamping, bending, stretching, etc. A general definition is parts with constant thickness during processing.

Sheet metal processing is a key technology that sheet metal technicians need to master, and it is also an important process of sheet metal product forming. What are the technical characteristics of sheet metal processing? The small edition of sheet metal processing manufacturers will introduce it to you.

1. High power density of sheet metal processing: The workpiece of sheet metal processing in the chassis cabinet absorbs the rapidly rising temperature during the sheet metal process, and even melts or evaporates when it is made of high melting point, high hardness, and high brittle materials (such as ceramics, diamonds, etc.). Can also be used for sheet metal processing;

1. High power density of sheet metal processing: The workpiece of sheet metal processing in the chassis cabinet absorbs the rapidly rising temperature during the sheet metal process, and even melts or evaporates when it is made of high melting point, high hardness, and high brittle materials (such as ceramics, diamonds, etc.). Can also be used for sheet metal processing;

2. Sheet metal processing beams are easy to control: easy to combine with precision machinery, precision measurement technology, electronic computers, etc., to achieve high precision and high automation.

3. Sheet metal processing is convenient and flexible: robots can process sheet metal in harsh environments or in places that are inaccessible to others.

4. Sheet metal processing is widely used: the divergence angle of the beam of light in sheet metal machining can be less than 1mm arc, the spot diameter can be less than micron, and the working time can be as short as nanoseconds and picoseconds. At the same time, the continuous output power of high-power sheet metal processing can reach the kilowatt level to ten kilowatts. According to the characteristics of the welding process, three welding methods are used in industrial production.

5. Compared with the production and processing of forgings and castings, sheet metal parts have the advantages of light weight, saving metal materials, simple processing technology, reducing production costs, and saving production costs.

6. Most welded sheet metal parts have low machining accuracy and large welding deformation, so the amount of deformation and correction after welding is very large

7. Since the welded parts are non-removable and difficult to repair, it is necessary to adopt reasonable assembly methods and procedures to reduce or avoid waste products. Large or oversized products usually need to be assembled on site, so a trial assembly should be carried out in the factory first. During the trial assembly, removable connectors should be used to temporarily replace non-removable connectors.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque