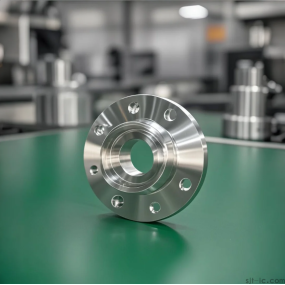

The Metal Stamping die belongs to a kind of stamping die. It takes the metal sheet as the processing object. The precision stamping parts processing factory tears, cuts, separates, presses, stretches, etc. the sheet through the punch (or hydraulic press) and the die to form various shapes that meet the needs of customers. Then it is composed of those parts:

1. Upper die base: hanging die lock punch, with guide sleeve, strong pressing spring, vibration isolation and buffering effect, the die will oscillate greatly during high-speed production, and the die base can play a buffering force, so the thickness of the die base needs to be thicker than other templates, generally around 50. With S45 #steel, the material has no heat treatment, and the hardness is relatively soft, which can protect the punch channel.

2. Upper backing plate: mainly pad punches. The 45 #steel raw material of the upper die seat is relatively soft. If the punch is directly in contact with the die seat, pits will easily occur, so replace it with a backing plate. Before forming the die, the through hole should be chamfered to remove burrs;

3. Upper splint: the effect of installing auxiliary guide sleeves and fixing punches, also known as punch fixing plates, the template holes can be chamfered;

4. Stopper plate: the effect of locking the guide needle and stripping plate into the block, the inner hole can be chamfered with the periphery of the template;  5. Stripping plate: its purpose is to place the unloading blade to ensure the accuracy of the orientation. When the cutting of the punch is completed, the force supplied by the unloading spring separates the punch from the stamping material.

5. Stripping plate: its purpose is to place the unloading blade to ensure the accuracy of the orientation. When the cutting of the punch is completed, the force supplied by the unloading spring separates the punch from the stamping material.

6. Lower template: The lower template is also called the knife edge fixing plate, which fixes the lower mold knife edge into the block, bending mold, floating material block, guide plate, auxiliary guide sleeve, and the template frame mouth is not allowed to be chamfered, and others can be chamfered;

7. Lower backing plate: the effect of padding the lower mold parts, the front of the blanking via hole cannot be chamfered, so as to avoid too large a chamfer and simply jam the waste, causing material blockage, and other holes can be chamfered, but the reverse chamfered of the floating pin via hole cannot be too large, just pour the burr.

8. Lower die holder: The effect of the lower die holder is similar to that of the upper die holder.

Of course, the above is just the structure of the general mold, not all molds are like this. According to the actual situation and customer requirements, combined with technology and cost control, the molds produced are different. In addition, depending on the product, the durability of the molds made by the precision stamping parts processing factory is also different, and each factory is also different.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque