Sheet Metal Processing, as an important raw material in the machinery industry, has formed a complete processing and manufacturing system, which is also one of the important processes in the production of mechanical technology. However, with the progress of industry, sheet metal processing technology also needs to be updated, breaking the process bottleneck of traditional sheet metal processing technology, and improving the effective level of the overall process as a development goal. To achieve this step of improvement, we must start to break through the difficulties of sheet metal shell processing technology in order to drive the process as a whole. Sheet metal processing companies provide a breakthrough for the improvement of sheet metal processing technology level.

1. Difficulties in sheet metal processing

1. Difficulties in sheet metal processing

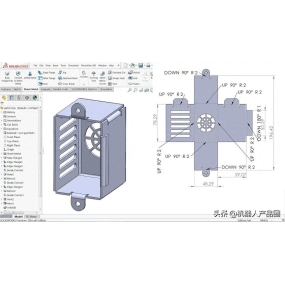

The main body of sheet metal processing technology is to process the metal sheet formed by the initial processing of sheet metal according to the mold and drawings, so as to form the required style and size, and then re-process and splice by welding to make the processed sheet metal sheet into a finished product. Through sheet metal processing technology, a variety of important sheet metal products can be manufactured, including power protection cabinets, industrial control cabinets, high and low voltage switchgear cabinets, communication cabinets, etc. These finished products are also important industrial products in the machinery industry. Sheet metal processing technology is simply referring to the needs of the manufacturer, through the help of mold drawings to produce finished products that meet the size and style. Among them, the processing process of sheet metal mainly includes cutting, bending, welding, surface treatment and assembly. In order to save raw materials and improve the processing efficiency of sheet metal processing technology, the processing methods often used in sheet metal processing technology, while paying attention to the appearance of the product, also require error control within a very small range, which belongs to the category of finishing and conforms to the production standards of its finished products. With the continuous innovation of our country‘s industry, the requirements for sheet metal processing technology are also getting higher and higher. Due to the different design methods required for different sheet metal structures, the design is non-fixed and non-modular, which poses many challenges to sheet metal processing and becomes a specific difficulty in upgrading the sheet metal processing technology.

2. Improvement measures for sheet metal processing technology

(1) Strictly implement the selection of sheet metal processing materials to ensure the quality level of processing materials

In order to optimize the sheet metal processing technology, it is also necessary to work hard on the selection of basic raw materials, and set the selection of materials as the primary goal in the sheet metal processing technology. First of all, we must understand that the finished products of the sheet metal processing technology are mostly used in cabinets. As the shell of the cabinet, its protection and stability are used, and the requirements for raw materials are very high. While strictly selecting materials, we must also pay attention to the cost performance of materials, try to save production costs, and further improve the material utilization rate of sheet metal raw materials in the production process. The whole process of sheet metal processing technology should be carried out in strict accordance with the process requirements of no more than three kinds of sheet metal thickness materials of the same specification, so as to avoid waste and increase costs. To control the sheet metal processing technology well, it is also necessary to proceed from the actual situation, combine the material‘s contour, shape and other requirements, and select raw materials that are similar to the size of the processed finished product, so as to improve the integrity and unity of the product. According to this requirement, if the finished product is exposed, it is also necessary to combine the texture of the raw materials of the sheet metal processing process, and strictly select the raw materials according to the standard of product appearance. After ZUI, in order to ensure that the quality of the material selection meets the standard, strict quality inspection is also implemented to effectively ensure the comprehensive quality level of the processed materials.

(2) Rational use of structural design and complete planning of welding structures

In the sheet metal processing technology, it is necessary to rationally use the structural design and plan the required welding structure. It is not only necessary to ensure the appearance of the finished product after the sheet metal processing technology Z, but also to ensure its practicality, and do every work step to improve the details of the product. This requires more effort in welding gaps and other details, and fine processing, such as welding technology. Nowadays, the welding processes commonly used in sheet metal processing technology mainly include the following, such as argon arc welding, carbon dioxide shielded welding, manual welding and gas welding. In the face of various welding processes, it is also necessary to rationally use the structural design and complete planning of the welding structure to ensure that the product is produced under the welding process that meets the requirements, so it is necessary to adopt the best welding method. The welding structure should also be analyzed from multiple levels. The first thing to do in the sheet metal processing process is to reserve the structure before the welding process. Only with the reserved structure can the process products avoid the lack of operating space and the subsequent process cannot be carried out. At the same time, when ensuring the avoidance of huge waste of sheet metal materials, in the welding operation of sheet metal components, the joint treatment of welding time and welding joints should be done well. The design and treatment of solder joints should ensure that the product is beautiful while doing a good job of welding, and the product should be leveled and trimmed to ensure that the product quality is up to standard and the appearance is up to standard.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque