The grinder should be maintained and used by a special person, and regularly inspected to ensure that the machine is in good condition.

1. After the operation is completed, all parts of the machine, especially the sliding parts, should be wiped clean and then oiled.

2. Remove grinding debris from all parts of the grinder.

3. Necessary parts, rust-proof.

Precautions for maintenance of the above grinder

1. Before grinding, please correct the wheel balance.

2. Grinding wheels must be carefully selected according to the material and hardness of the workpiece.

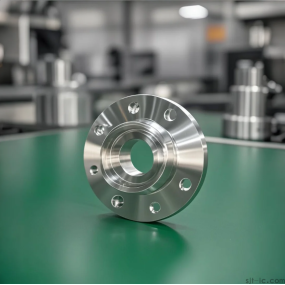

3. The spindle end and the grinding wheel flange should be coated with a thin oil film to prevent rust.

3. The spindle end and the grinding wheel flange should be coated with a thin oil film to prevent rust.

4. Please pay attention to the direction of rotation of the spindle.

5. Prohibit the use of air guns to clean crops and machinery.

6. Please pay attention to whether the oil passage of the oil window is smooth.

7. Vacuum box, filter steel, please clean it once a week.

8. When the suction force is weak, please check whether the vacuum pipe is blocked with powder chips.

9. It is necessary to keep the vacuum pipe clean, otherwise it will cause combustion.

Maintenance of grinding machine suction cups

The disk surface of the permanent magnetic casting chuck or electromagnetic chuck is the basis for the grinding accuracy of the working object, and should be properly maintained and maintained. If the accuracy of the working object is poor or the disk surface is damaged, the disk surface must be ground again, and the disk surface accuracy meets the requirements to ensure the accuracy of the working object.

Maintenance of grinder lubrication system

The lubricating oil should be replaced for one month at first, and then every 3-6 months. There is an oil drain plug under the oil tank, which can be used. Please note that when changing the oil, clean the inside of the tank and the filter together.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque