1. When machining parts, the protective door must be closed, and it is not allowed to stretch the head or hands into the protective door. It is not allowed to open the protective door during processing.

2. During the processing, the operator shall not leave the machine without authorization. He shall maintain a high degree of concentration and observe the running state of the machine. In the event of an abnormal phenomenon or accident, the program operation shall be terminated immediately, the power supply shall be cut off and the instructor shall be promptly reported. No other operations shall be carried out.

3. It is strictly forbidden to slap the control panel and touch the display screen hard. Strictly prohibit tapping on the workbench, indexing head, fixture and guide rail;

4. It is strictly forbidden to open the numerical control system control cabinet for viewing and touching;

5. Operators are not allowed to change the internal parameters of the machine tool at will. Intern students are not allowed to call or modify other programs that are not written by themselves;

5. Operators are not allowed to change the internal parameters of the machine tool at will. Intern students are not allowed to call or modify other programs that are not written by themselves;

6. On the machine tool control microcomputer, no other operations are allowed except for program operation, transmission, and program copying.

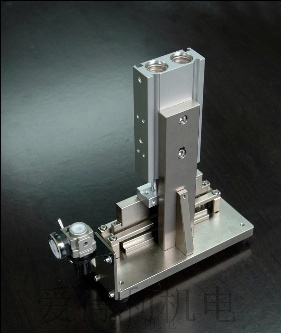

7, numerical control milling machine belongs to large precision equipment, in addition to the workpiece and workpiece on the workbench, the machine is strictly prohibited to stack any work, clip, blade, measuring tool, workpiece and other sundries;

8. It is forbidden to touch the knife tip and iron filings with your hands. Iron filings must be cleaned with iron hooks or brushes.

9. Do not touch the rotating spindle, workpiece, or other moving parts by hand or any other means.

10. It is forbidden to measure workpieces during processing, manually shift gears, and not to wipe workpieces with cotton wire or clean machine tools.

11. Prohibit attempts to operate.

12. When using the handwheel or fast moving mode to move the position of each axis, be sure to see the ", -" signs in each direction of the X, Y, and Z axes of the machine before moving. When moving, turn the handwheel slowly to observe that the moving direction of the machine is correct before accelerating the moving speed;

13. When the measurement of the workpiece size must be suspended during the operation of the program, the measurement can only be carried out after the machine is completely stopped and the spindle is stopped to avoid personal accidents.

14. If the machine is not used for several days, the NC and CRT parts should be powered on for 2-3 hours every other day.

15. When shutting down, wait for the spindle to stop for 3 minutes before shutting down.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque