High-precision CNC Machining of automotive parts: a comprehensive guide

CNC (computer numerical control) machining has revolutionized the manufacturing industry, especially in the field of production of automotive parts. Automotive parts are often required to meet very strict tolerance, high performance and durability standards. High-precision CNC machining plays a key role in ensuring that these specifications meet stringent standards. This article will explore why CNC machining is critical to automotive parts, the types of automotive parts that can be manufactured, how to achieve high-precision results and a breakdown of the catalogue of automotive parts of different brands. In addition, we will discuss the role of suppliers such as Great Light in providing advanced machining solutions.

High-precision CNC machining of automotive parts

High-precision CNC machining of automotive parts

Why use CNC machining to fabricate automotive parts?

CNC machining is a manufacturing method that uses computer-controlled machines to cut, milling, drilling, and shaping materials with high precision. The application of CNC machining in the automotive industry is essential for producing parts that require complex designs and tight tolerances. Here are a few reasons why CNC machining is favored in automotive manufacturing:

1. Precision and accuracy

Automotive components, especially those in high-performance engines and drivetrains, must meet strict dimensional and performance tolerances. CNC machining enables extremely high precision, often within microns, which is required for automotive components.

2. Complex geometries

CNC machines are capable of machining complex geometries that are difficult or impossible to achieve using traditional manufacturing methods. Parts such as engine blocks, cylinder heads, and transmission components benefit from CNC‘s ability to create complex and detailed designs.

3. Consistency and repeatability

CNC machines can produce parts of the same specification over thousands of iterations, ensuring consistent quality and consistency. This is critical in automotive manufacturing, as each part must perform exactly the same to ensure the vehicle‘s overall performance and safety.

4. Material flexibility

CNC machining can handle a wide variety of materials commonly used in automotive manufacturing, including metals (aluminum, steel, titanium), plastics, and composites. This material versatility allows manufacturers to choose the best material for each specific part, balancing cost, weight, and performance.

5. Faster prototyping and production

CNC machining enables rapid prototyping, which is essential for testing and improving designs before mass production. In addition, it can be integrated into automated manufacturing processes, reducing lead times and enabling on-time production for automotive suppliers.

6. Suitable for small and large-scale production, cost-effective

Although the initial set-up cost of CNC machining can be high, the total unit cost decreases significantly as production scales up. In addition, for small and medium batches, CNC machining is usually more economical than traditional manufacturing methods such as casting or forging.

Automotive parts that can be manufactured using CNC machining

The precision, flexibility and efficiency of CNC machining make it an ideal solution for manufacturing a wide range of automotive parts. Below is a comprehensive table showing the wide range of automotive parts that can be manufactured using CNC machining:

Model Name Location Material Name Performance Parameters Requirements Ford Mustang 2020 Engine Cylinder Block Engine Aluminum Alloy High Strength, Heat Resistance, Dimensional Accuracy Chevrolet Camaro 2021 Cylinder Head Engine Cast Aluminum High Thermal Conductivity, High Dimensional Accuracy 2022 BMW 3 Series Timing Gear Engine Steel Alloy Wear Resistance, Dimensional Stability under Stress Audi A4 2023 Transmission Housing Spread Aluminum Strength, Heat Resistance, Dimensional Accuracy Tesla Model 3 2022 Brake Caliper Brake System High Strength Steel Durability, Dimensional Accuracy, Heat Resistance Honda Civic 2022 Crankshaft Engine Steel Strength, Balance, Precision Machining Mercedes Benz C-Class 2023 Valve Holder Engine Titanium Alloy Lightweight, Corrosion Resistance, High Temperature Resistance Ford F-150 High durability, high surface accuracy for key fits Porsche 911 2022 Suspension components Suspension aluminum alloy Light weight, fatigue resistance, high precision Toyota Corolla 2023 steering knuckle Steering system Steel alloy High strength, wear resistance, corrosion resistance

Automotive parts that can be manufactured using CNC machining

Automotive parts that can be manufactured using CNC machining

These automotive parts are all highly complex and require the precision, repeatability, and flexibility that CNC machining provides. Each of the parts listed above has specific performance parameters that must be met to ensure the vehicle operates as intended, such as heat resistance, strength, abrasion resistance, and dimensional accuracy.

How to achieve high-precision CNC machining of automotive parts?

To achieve high-precision CNC machining of automotive parts requires a combination of the right technology, skilled technicians, and well-defined processes. Here‘s how to ensure accuracy during CNC machining:

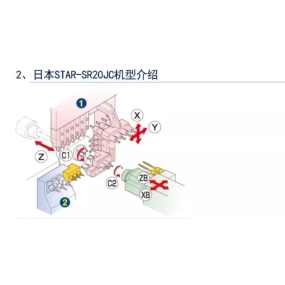

1. Advanced numerical control machine

The use of high-quality CNC machines is fundamental to ensuring accuracy. Machines with high spindle speeds, advanced tools, and precise control mechanisms are essential for the production of automotive parts with tight tolerances. Common CNC machine types used for automotive parts include CNC milling machines, CNC lathes, and CNC routers.

2. Precision tools and cutting tools

The quality of cutting tools such as end mills, drills, and taps plays a crucial role in the accuracy of machined parts. Specialized tools for high-precision machining, including carbide and diamond-coated tools, ensure minimal wear during machining.

3. Quality control system

To ensure that each part meets the required specifications, manufacturers use advanced quality control systems. These systems include laser measurement systems, coordinate measuring machines (CMMs), and optical inspection equipment to verify the dimensional accuracy and integrity of each part.

4. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software

CAD and CAM software allows for the precise design and simulation of parts before machining begins. This step ensures that the part design is optimized for machining, thus minimizing errors. Software such as Siemens NX, AutoCAD, and Mastercam are commonly used to plan and execute machining processes.

5. Material selection

Selecting the right material is a critical step in ensuring the performance of automotive parts. CNC machining allows for the precise processing of a wide variety of materials, each selected for its specific performance requirements. Whether it is high-strength steel for durability or aluminium for lightweight applications, choosing the best material is critical to achieving high-precision results.

6. Skilled technicians

Even with the best equipment, skilled technicians are needed to ensure that CNC machines are set up and operated correctly. Experienced mechanics are essential for monitoring the production process, making adjustments as needed, and ensuring that the final product meets all performance standards.

How to achieve high-precision CNC machining of automotive parts

How to achieve high-precision CNC machining of automotive parts

Popular Brand Auto Parts Swap List

Below is a list of interchangeable automotive parts from well-known brands. This catalog helps streamline the procurement process and ensures that manufacturers and suppliers can quickly find compatible parts.

Atlas Auto Parts Swap List

Part Name Compatible Model Material Location Engine Block Atlas A1, Atlas B2, Atlas C3 Aluminum Engine Cylinder Head Atlas A1, Atlas B2 Cast Aluminum Engine Valve Guide Atlas A1, Atlas B2, Atlas C3 Steel Alloy Engine

Clip House Auto Parts Swap List

Component Name Compatible Model Material Location Timing Chain Guide Rail Clip Home X1, Clip Home Y2 High Strength Steel Engine Crankshaft Pulley Clip Home X1, Clip Home Z3 Steel Alloy Engine

Dz Auto Parts Catalog

Part Name Compatible Model Material Location Steering Knuckle Dz 200, Dz 300 Steel Alloy Steering System Gearbox Housing Dz 200, Dz 250 Aluminum Alloy Spread

Sti Automotive Valve Mechanism Parts List

Part Name Compatible Model Material Location Valve Holder Sti Turbo Series, Sti ST-R Titanium Engine Valve Spring Sti Turbo Series, Sti ST-R Steel Engine

Daguang: Leading supplier of high-precision numerical control processing of automotive parts

As a leading provider of high-precision CNC machining services, Great Light provides advanced solutions for the rapid manufacturing of complex automotive parts. Their expertise lies in the production of high-precision and durable automotive parts using cutting-edge CNC machines and materials. In addition to precision machining, Great Light also offers rapid prototyping services, ensuring rapid delivery of prototypes for testing and validation.

Services provided by Great Light:

High Precision CNC Machining: Specializes in engine components, transmission components, suspension systems, and more. Rapid Prototyping: Rapid turnaround of prototype components that can be tested prior to mass production. Post-processing and Finishing Services: Includes heat treatment, surface coating, and other finishing processes. Custom Auto Parts: Great Light can produce custom parts to customer specifications, including certified automotive parts. Great Light‘s ability to work with a wide range of materials, including lightweight aluminum, high-strength steel, and advanced composites, makes it an ideal partner for automotive manufacturers. Their commitment to quality and precision ensures that every part meets the highest standards of performance and reliability.

conclusion

High-precision CNC machining is an essential tool in the manufacturing of automotive parts, with unparalleled precision, speed and material versatility. As the demand for complex, high-performance components continues to grow, CNC machining provides the solutions needed to meet these challenges. Whether it‘s engine blocks, transmission housings or suspension components, CNC machining allows manufacturers to produce parts that meet stringent performance and dimensional requirements.

For those seeking a reliable supplier of high-precision automotive parts, Great Light stands out as an industry leader, offering customized, high-quality parts at competitive prices.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole