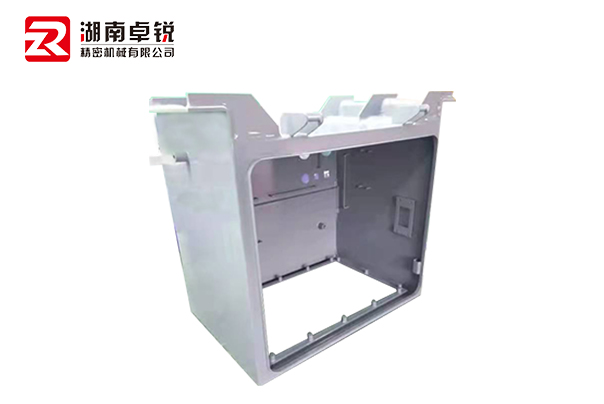

With the rapid development of industry, Sheet Metal Processing is more and more widely used in people‘s work and life. However, in the process of purchasing chassis cabinet sheet metal processing, many friends are unfamiliar with the product and often do not know how to distinguish the quality of sheet metal cabinet processing. So how should we distinguish the quality of sheet metal cabinet processing? The small edition of sheet metal processing manufacturers will introduce to you.

How to judge the processing quality of sheet metal cabinets:

How to judge the processing quality of sheet metal cabinets:

1. Look at the thickness of the board

The formed steel plate material can be tapped to know the thickness and thinness of the steel plate. If there is a bracket inside, it can be a little thicker than the sheet metal cabinet, which can withstand some heavier equipment.

2. Accessories inside the sheet metal cabinet

The inside of the sheet metal cabinet needs something to fix the cable, or it can be lifted a little at the bottom of the cabinet to facilitate wiring, and the screws for fixing the shelf need to be sufficient.

3. Look at the matching glass together.

The cabinet is generally transparent, and some glass needs to be installed to facilitate viewing to see if there are cracks around the glass. If there are cracks in the product during the processing of the sheet metal cabinet, it is recommended not to.

4. Look at the sprayed surface after the material is processed.

Products formed from materials processed by sheet metal cabinets need to be sprayed, and uniform spraying can achieve a good anti-rust effect.

In summary, the above content is a way to judge the processing quality of sheet metal cabinets. In most cases, we can judge the processing quality of sheet metal cabinets by looking at the thickness of the sheet metal, the internal accessories of the sheet metal cabinet, the matching glass, and the sprayed surface after the material is processed, so as to choose a suitable and high-quality sheet metal cabinet.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque