I often hear some customers complain that the stamping supplier they find is not good, and they will always increase costs in the follow-up or fail to make the perfect molds and stamping parts they want. This is because many precision stamping parts processing plants start making molds with drawings hastily when they get the order, which leads to difficulties in later mold assembly or proofing. Therefore, when receiving an order, the factory should analyze the drawings step by step to make a detailed plan. Only in this way can we avoid many problems to the greatest extent, and there will be no cost that is too high and they cannot make money, let alone annoy customers. So what work should a precision stamping parts processing plant do well?

1. Carefully analyze the drawings

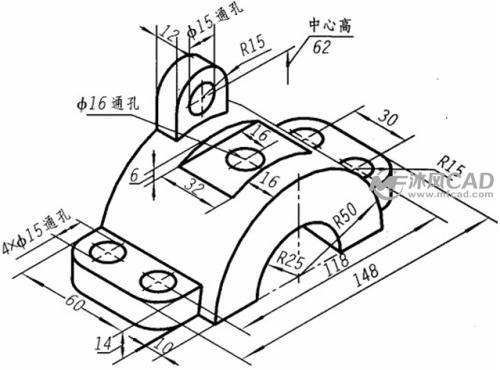

After receiving the hardware stamping drawings given by the customer, it is necessary to confirm the quantity of the product and the specific scale tolerance requirements with the customer as soon as possible, and then confirm what kind of process is used for production. According to the customer‘s requirements, a plan can be formulated to meet certain requirements. With skilled technology and a large number of practical cases, Hongneng can provide customers with more mature cost reduction solutions that meet product requirements, and meet customer requirements through various processes.

After confirming the production process with the customer, it is necessary to plan a reasonable discharge method to minimize the waste. This is not only to reduce costs from the customer‘s point of view, but also to reduce costs for the precision stamping parts processing plant itself.

2. Draw up a processing plan

After analyzing the drawings, it is necessary to formulate an overall processing plan. Some Metal Stamping products are not only achievable by the stamping process, but also include other processing techniques, such as riveting, welding, drilling, laser cutting, tapping, etc. This requires the development of a sequence of various processing techniques.

3. Confirm the number and shape of processing steps

The vast majority of stamping parts require multiple processes to be processed, and precision stamping parts processing plants must plan a reasonable number of processes. A decrease in the number of processes means a decrease in product costs.

After confirming the number of processing steps, it is necessary to understand the shape and size of the product after each step, and to confirm the size and shape of the product blank.

4. Planning of stamping dies

When planning a stamping die, it is necessary to ensure the operability and safety of the die. The wearing parts are also planned to be removable to facilitate future maintenance.

5. Select the right press

Calculate the required punching force based on the external dimensions and thickness of the metal stamping parts, and also consider that the scale of the punching table should match the scale of the product.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com!

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole