1. Precision parts processing and painting processing: Hardware factories use painting processing when producing large-scale hardware products. By painting, hardware parts can be avoided from rusting, such as daily necessities, electrical shells, handicrafts, etc

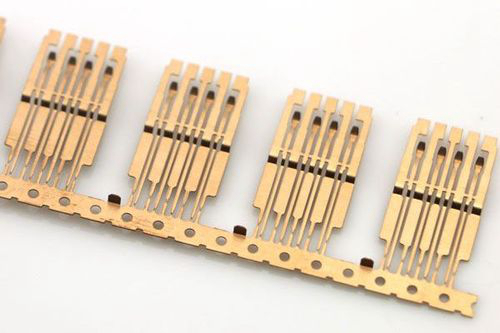

2. Electroplating: Electroplating is also one of the most common processing techniques for hardware processing. Through modern technology, the surface of hardware is electroplated to ensure that the product does not undergo mildew and embroidery after long-term use. Common electroplating processes include: screws, stamping parts, batteries, car parts, trinkets, etc.

3. Shenzhen hardware precision parts processing: Surface polishing is generally used in daily necessities for a long time. For example, by performing surface burr treatment on hardware products, we produce a comb. The comb is a hardware piece made by stamping, so the edges of the stamped comb are very sharp. We need to polish the sharp corners into a smooth face, so that it will not cause harm to the human body during use.

3. Shenzhen hardware precision parts processing: Surface polishing is generally used in daily necessities for a long time. For example, by performing surface burr treatment on hardware products, we produce a comb. The comb is a hardware piece made by stamping, so the edges of the stamped comb are very sharp. We need to polish the sharp corners into a smooth face, so that it will not cause harm to the human body during use.

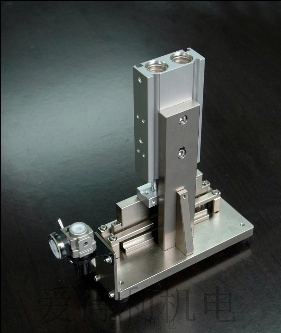

Turning the outer circular surface is the basic method of machining the outer circular surface in the machining of precision parts, and the equipment used is the lathe. In general machinery factories, lathes account for about 40% of the total number of machine tools. Turning is the main method of roughing and semi-finishing the outer surface of various materials, and it is also the final finishing method of various materials that are not suitable for grinding.

In single-piece small batch production, turning the outer circular surface is generally carried out on ordinary lathes. In mass production, multi-tool semi-automatic lathes or automatic lathes are widely used. Large disc parts should be machined on vertical lathes. For large long shafts, parts need to be machined on heavy-duty horizontal lathes.

The characteristics of the turning outer circular surface of Shenzhen hardware processing are:

1. Simple cutting tools, easy to manufacture, sharpen, and install.

2. The cutting process is smooth and the cutting force fluctuations are small, which is conducive to the use of high cutting speeds and improved productivity.

3. The machine has good versatility and can process external circles, end faces, internal holes, threads and chamfers in one clamping. The mutual position accuracy between the surfaces is easy to ensure;

4. Shenzhen hardware processing is suitable for the finishing of non-ferrous metal parts.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole