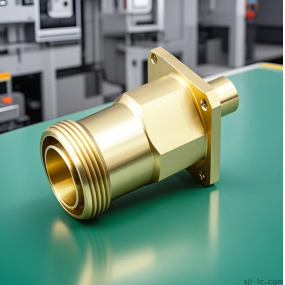

The stamping function of metal materials refers to the adaptability of metal materials to various stamping processes. Very important factors to be considered in stamping processing plants. For example, when a certain material is selected for stamping, the material is easy to process, the resulting stamping parts have high tolerance levels, good quality and high production efficiency, very little waste, and the chess pieces wear very slowly. It can be said that the stamping function of this material is good.

1. The influence of elasticity on stamping function

Blanking, punching, cutting, trimming and other separation processes are more suitable for metal materials with better elasticity. Metal materials with better separation elasticity can obtain good quality sections. Metal materials will rebound after twisting due to their elasticity, so that the twisting parts cannot reach the predetermined shape and size requirements. And the better the elasticity, the greater the rebound. The rebound of the twisting parts brings difficulties in production, and many man-hours are consumed when adjusting the working part of the die.

2. The influence of plasticity on stamping function

Deformation processes such as zigzag, deep drawing, and forming are all carried out according to the plasticity of metal materials. Metal materials with better plasticity have a large degree of deformation, which can reduce the number of steps and the number of central annealing times in stamping, and even do not need central annealing as one of the indicators of plastic deformation ability of metal materials. The uniform elongation of metal materials directly determines the stamping function of materials. In practice, such as the limit deformation degree of stamping, such as flanging coefficient, shrinkage coefficient, minimum bending radius, expansion coefficient, etc. can be directly or indirectly expressed by uniform elongation. Separation process requires that the material has appropriate plasticity. If the plasticity is too high, the material is too soft, and the punching is prone to large burrs, its size is not easy to meet the requirements. If the plasticity is too low, the material is too hard and brittle, and the mold is easy to wear

3. The influence of strength and hardness on stamping function

Metal materials have high strength and high hardness. The strength and hardness of materials are high, and their plasticity must be low. Therefore, metal materials with high hardness are unfavorable for deformation processes such as tortuous, deep drawing and forming. In general, the hardness of materials used in the deformation process of stamping processing plants is low, but metal materials with certain strength and hardness can obtain better section quality in the separation process.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque