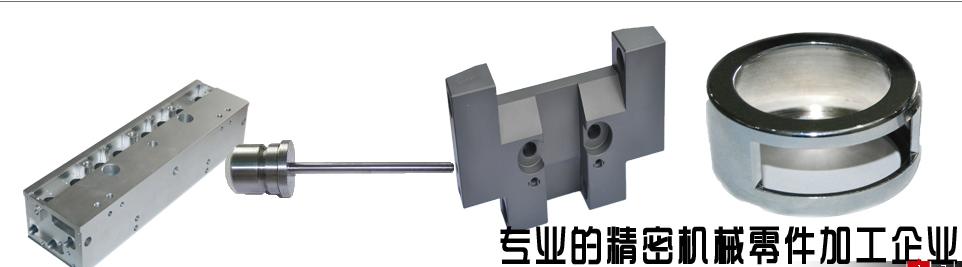

Shenzhen Machinery Precision Parts Machining is a process in which machining machinery is used to change the external dimensions or properties of a workpiece.

According to the temperature state of the workpiece to be processed, it is divided into cold working and hot working. Generally, it is processed at room temperature and does not cause chemical or phase changes of the workpiece, which is called cold working. Generally, processing above or below room temperature will cause chemical or phase changes of the workpiece, which is called hot working. Cold working can be divided into cutting and pressure working according to the difference in processing methods. Hot working commonly includes heat treatment, calcination, casting and welding.

Shenzhen machinery precision parts processing includes: machining includes: filament power windings, laser cutting, heavy-duty machining, metal bonding, wire cutting, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending, die forging, water jet cutting, precision welding, etc.

Shenzhen machinery precision parts processing includes: machining includes: filament power windings, laser cutting, heavy-duty machining, metal bonding, wire cutting, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending, die forging, water jet cutting, precision welding, etc.

In addition, hot and cold treatment is often used during assembly. For example, when the bearing is assembled, the inner ring is often cooled in liquid nitrogen to shrink its size, and the outer ring is properly heated to enlarge its size, and then it is assembled together. The outer ring of the wheel of the train is also heated to the base, which can ensure the firmness of its bonding when cooled (this method is still used in the assembly process of some parts).

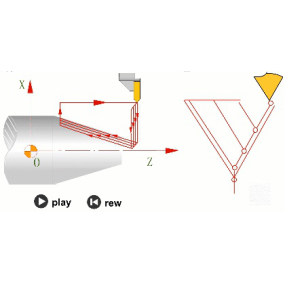

Machining of precision parts: Machining in a broad sense refers to the process of manufacturing products by mechanical means; in a narrow sense, it is the process of making parts with special machinery such as lathes, milling machines, drilling machines, grinders, stamping machines, and die-casting machines.

Then what do you know about the commonly used machinery in Shenzhen machining? Let‘s take a look.

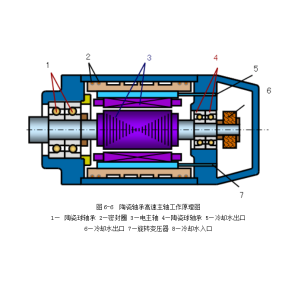

Common machinery for machining in Shenzhen: Machinery required for machining consists of digital display milling machines, digital display forming grinders, digital display lathes, EDM machines, universal grinders, machining centers, laser welding, medium wire, fast wire, slow wire, cylindrical grinders, internal grinding machines, precision lathes, etc., which can be used for turning, milling, planing, grinding, etc. of precision parts. Such machinery is good at turning, milling, planing, grinding, etc. of precision parts, and can process various irregular-shaped parts with a machining accuracy of up to 2μm.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque