The practicality and characteristics of precision parts processing in Shenzhen

Shenzhen precision parts processing is very practical in real life. Why do you say that?

Shenzhen precision parts processing is very practical in real life. Why do you say that?

Because when a machine is working, it needs some good parts to maintain the normal operation of the machine, so this precision part is a good choice. Many ordinary parts will appear during work, such as rust or damage.

But if you use this precision parts processing, there will be almost no such similar problems, so this precision part is a very good and useful part that should be well promoted in real life.

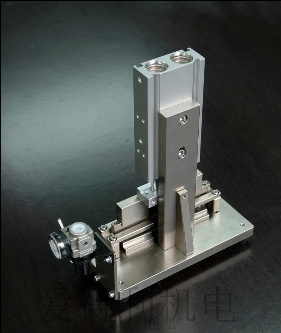

The main features of Shenzhen precision parts processing are: a precision fully automatic lathe with five sets of tool holders, each equipped with a thousand-point card to fine-tune the workpiece to achieve high precision; more than 10 knives can be installed according to the workpiece processing process.

Two-axis device; the spindle adopts an electromagnetic clutch to drive the tapping spindle, and uses the rotation difference between the high-speed rotation and the mechanical spindle in the same direction to perform tapping. The two axes can be shaken to change processing, and the twisted hole and tapping inner and outer teeth can be processed at the same time.

Since the five tools and two tail shafts of the machine tool can work simultaneously during processing, this machine tool is 4 to 6 times faster than the numerical control machine tool to process parts.

Complex parts can be synchronized for processing such as outer circle, spherical surface, conical surface, arc surface, step, cutting groove, drilling, tapping, die, embossing, cutting, etc., all processing steps can be completed at one time, with high processing accuracy, no need for manual operation, automatic feeding is fully automated, and one person can watch multiple sets.

At the same time, the milling device can also be used to process external threads, completely solve the problem of difficult machining of die teeth, and can process double-headed threads. The structure is precise, and the production is controlled by the cam. The cam completes the processing of a part every turn. The cam rotates at 1.0~ 36 rpm, which can be adjusted according to different processed parts, and can process 36 parts per minute at the fastest.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque