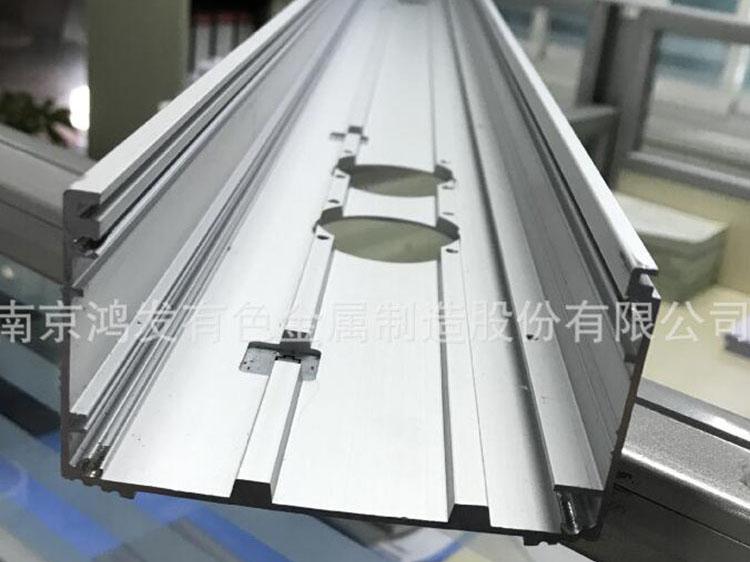

CNC Machining of aluminum parts has higher precision than ordinary deep machining, so the price of CNC machining is also higher than that of ordinary deep machining. So how is the CNC price of aluminum parts calculated?

1. Calculate processing costs based on the processing steps

This calculation method is very simple, it is how much it costs to drill a hole, how much it costs to drill a thread, and how much it costs to mill one square centimeter Then multiply by the number of holes to be processed, the area to be milled, and add up these amounts to obtain the price for CNC machining of an aluminum component. If there are too many holes on the aluminum part, such as the vacuum adsorption plate of a printer, and there are hundreds of holes on one piece, the unit price of processing holes can be slightly lower.

2. Calculate prices based on processing hours

Pricing by working hours means how much it costs to process an hour. Of course, the longer the working hours for more complex products, the higher the processing cost. The working hours are also calculated in advance, such as how long it takes to process a hole, how long it takes to mill a flat surface, and then the total required working hours are calculated by adding up all the working hours of the processing steps.

Generally speaking, batch CNC machining is cheaper than aluminum sample making, as sample making involves programming, calibration, and other time-consuming processes. The large-scale processing of aluminum parts is relatively easy, but it only requires equipment loss and less labor.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque