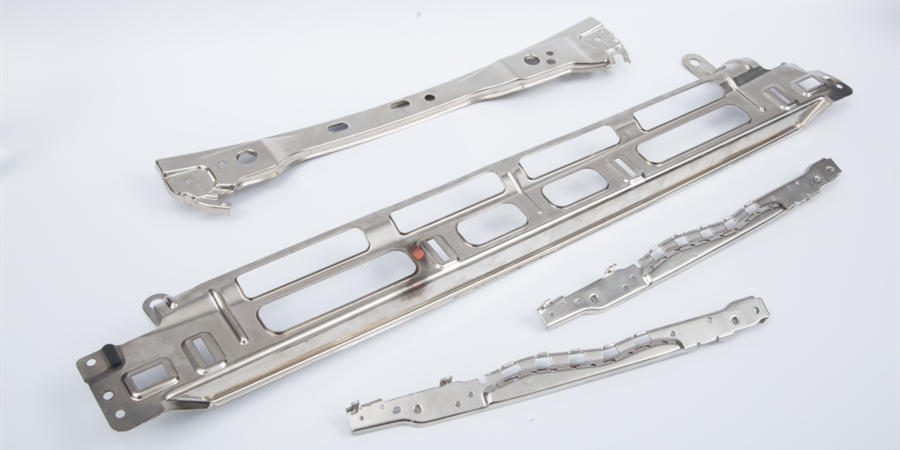

With the continuous improvement of science and technology and people‘s living standards, people have higher and higher requirements for the fineness of products. In the stamping industry, people‘s demand for precision stamping parts is also expanding. Precision stamping parts not only have high fineness, but also have advantages in appearance and durability that ordinary stamping products do not have. The production process of precision stamping parts is more complicated than that of ordinary stamping parts. It is not only necessary to consider the shape and size of the product, but also to consider stamping dies, punches and other matters when producing. In order to ensure the production of qualified precision stamping parts, there are generally many things that need to be paid attention to in the production:

1. It is necessary to regularly check the performance of the punching machine and the parallelism and verticality of the slider and the table.

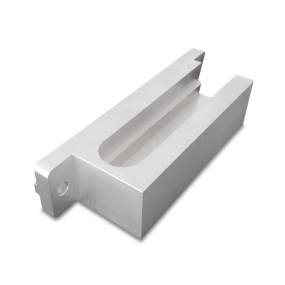

2. Strict equipment requires the production of precision stamping dies. If the stamping factory does not have the ability to develop molds, it must find a more regular and powerful mold factory. The quality of precision stamping dies determines the quality of precision stamping parts. In terms of molds, you must not find an irregular and powerless mold factory in order to save money.

3. Before installing the mold, be sure to check whether the mold and the punch table are clean, and check the lubrication status of the mold guide column.

4. Check the replacement spring regularly during the production process to avoid spring problems affecting the quality of precision stamping parts.

5. When installing stamping dies, stamping workers must adhere to the established rules and regulations.

6. During the actual production process, if the die edge is worn, it must be repaired or replaced in time, otherwise it will lead to increasing damage to the die.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque