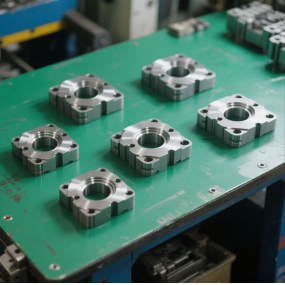

Introduction to Shenzhen Machinery Precision Parts Processing:

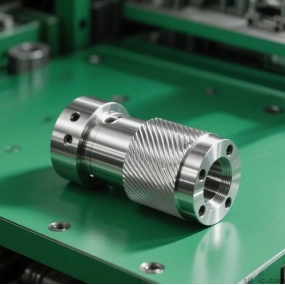

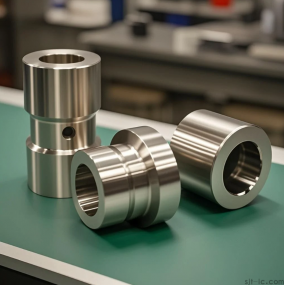

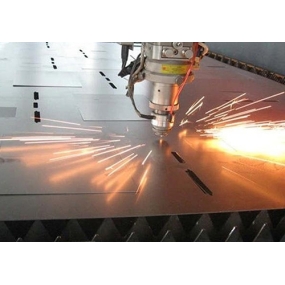

Machining of mechanical precision parts refers to the process of changing the external dimensions or properties of a workpiece through a mechanical device. Shanghai Piney Technology Hot Processing Cold Processing can be divided into cutting processing and pressure processing according to the difference in processing methods. Hot processing commonly includes heat treatment, forging, casting and welding.

Machining of mechanical precision parts refers to the process of changing the external dimensions or properties of a workpiece through a mechanical device. Shanghai Piney Technology Hot Processing Cold Processing can be divided into cutting processing and pressure processing according to the difference in processing methods. Hot processing commonly includes heat treatment, forging, casting and welding.

Second, the production types of Shenzhen machinery precision parts processing:

1. Single-piece production: Products of different structures and sizes are produced individually, and are rarely repeated.

2. Mass production: Manufacture the same product in batches throughout the year, with a certain degree of repetition in the manufacturing process.

3. Mass production: The number of products manufactured is large, and most workplaces often repeat the processing of a certain part in a certain process.

III. Classification of Shenzhen machinery precision parts processing:

1. Design reference: The reference used to determine the position of other points, lines, and surfaces on the part drawing is called the design reference.

2. Process reference: The reference used in the machining and assembly process of parts is called process reference. Process reference is divided into assembly reference, measurement reference and positioning reference according to different purposes.

(1) Assembly reference: The reference used to determine the position of a part in a component or product during assembly is called an assembly reference.

(2) Measurement datum: The datum used to check the size and position of the machined surface is called the measurement datum.

(3) Positioning datum: The datum used for positioning the workpiece during processing is called the positioning datum. As the positioning datum surface (or line, point), only the unprocessed rough surface can be selected in the first step, and this positioning surface is called the rough datum. In subsequent processes, the machined surface can be used as the positioning datum, and this positioning surface is called the fine datum.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque