According to the analysis of the causes of accidents in the general processing of precision stamping parts, accidents in stamping work are mainly caused by the following reasons:

1. Hazards arising from the structure of the punch itself

At this stage, the vast majority of punches still use rigid clutches. Once the clutch connection is running, a stamping cycle must be completed before the slider will stop running. If the stamping worker‘s hand cannot be taken out of the mold in time during the downpunching process, it will cause a stamping injury.

2. Problems occur during the processing of precision stamping parts

During the operation of the punch, there will be shock and vibration, which will cause the parts of the punch to deform, wear and even break over time, resulting in the loss of control of the punch and the continuous impact phenomenon, which is a very dangerous situation.

3. The switch fault of the punch press

The switch of the punching machine malfunctions due to man-made or long-term lack of maintenance, resulting in malfunction during the stamping process.

4. Unreasonable design of stamping dies

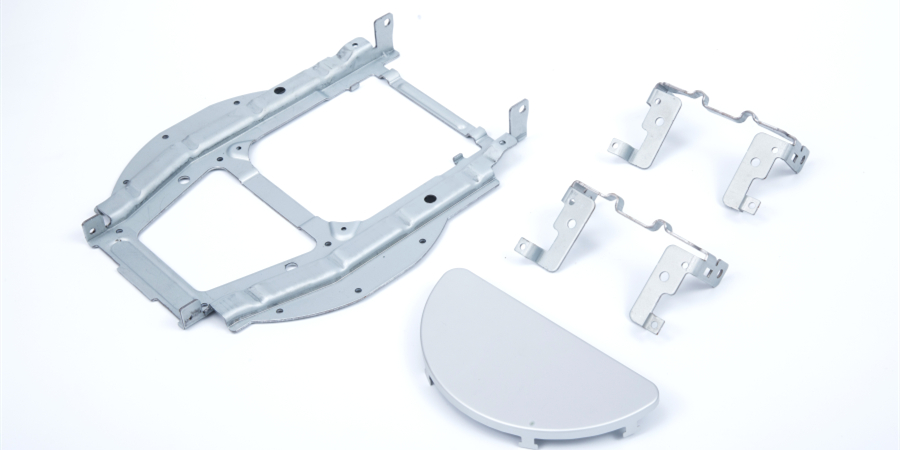

Stamping dies are the foundation for producing precision stamping parts. Improper stamping die design will greatly increase the possibility of stamping accidents. Normal stamping dies will also be worn, deformed or damaged with the increase of use time, resulting in accidents.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque