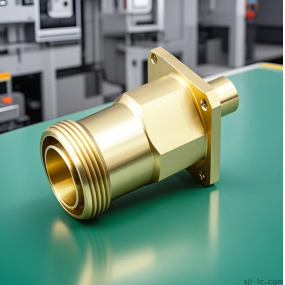

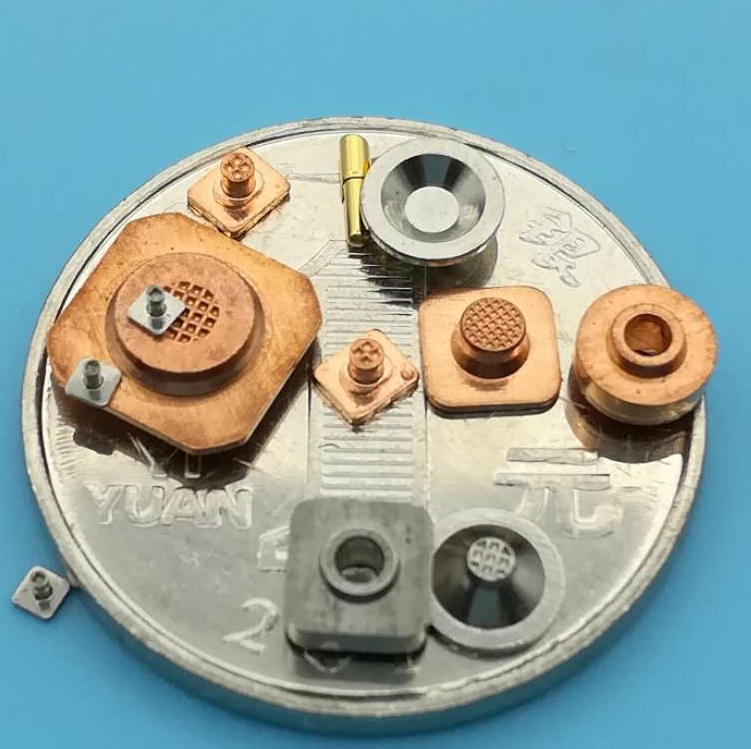

EMAR will reveal the difference between precision cold extrusion technology and ordinary cold extrusion technology for you: 1. The processing equipment is different. The precision cold extrusion processing equipment is a precision high-speed punch, and the ordinary cold extrusion processing equipment is a hydraulic press of 20-1200 tons. 2. The processing dies are different. Precision cold extrusion is generally an extended continuous die, and ordinary cold extrusion is an ordinary multi-block sub-die. 3. The processing efficiency is different. The daily output of precision cold extrusion single die can reach 200,000 particles, and the daily output of ordinary cold extrusion multi-process products is 2000-10000 pieces. 4. The precision is not the same. The precision of precision cold extrusion products can reach 0.02mm, and the precision of ordinary cold extrusion products can reach 0.05mm. It is very good. 5. The processing procedures are different. Precision cold extrusion is formed through multiple steps of continuous die. Ordinary cold extrusion is annealed and then phosphorized to saponify multiple die forging extrusion finished products. 6. Product sizes are different. Precision cold extrusion generally makes small hardware parts with a diameter of less than 15mm, and ordinary cold extrusion makes large hardware parts with a diameter of more than 15mm. EMAR Hardware has been focusing on precision cold extrusion technology for 20 years. It has created an original continuous die precision feeding technology process to meet customers‘ requirements for product quality and quantity.

EMAR will reveal the difference between precision cold extrusion technology and ordinary cold extrusion technology for you: 1. The processing equipment is different. The precision cold extrusion processing equipment is a precision high-speed punch, and the ordinary cold extrusion processing equipment is a hydraulic press of 20-1200 tons. 2. The processing dies are different. Precision cold extrusion is generally an extended continuous die, and ordinary cold extrusion is an ordinary multi-block sub-die. 3. The processing efficiency is different. The daily output of precision cold extrusion single die can reach 200,000 particles, and the daily output of ordinary cold extrusion multi-process products is 2000-10000 pieces. 4. The precision is not the same. The precision of precision cold extrusion products can reach 0.02mm, and the precision of ordinary cold extrusion products can reach 0.05mm. It is very good. 5. The processing procedures are different. Precision cold extrusion is formed through multiple steps of continuous die. Ordinary cold extrusion is annealed and then phosphorized to saponify multiple die forging extrusion finished products. 6. Product sizes are different. Precision cold extrusion generally makes small hardware parts with a diameter of less than 15mm, and ordinary cold extrusion makes large hardware parts with a diameter of more than 15mm. EMAR Hardware has been focusing on precision cold extrusion technology for 20 years. It has created an original continuous die precision feeding technology process to meet customers‘ requirements for product quality and quantity.

https://tieba.baidu.com/p/5487286263

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque