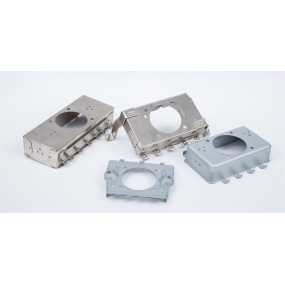

Shenzhen precision parts processing mainly has fine turning, fine boring, fine milling, fine grinding and grinding processes.

Then do you know the method of Shenzhen precision parts processing, how to operate it in processing, and how much is the gap? Let‘s take a look.

Then do you know the method of Shenzhen precision parts processing, how to operate it in processing, and how much is the gap? Let‘s take a look.

Shenzhen precision parts processing method:

① Finishing and finishing boring: Most of the precision light alloy (aluminum or magnesium alloy, etc.) parts of the aircraft are mostly processed by this method. Generally, natural single-crystal diamond tools are used, and the arc radius of the blade is less than 0.1 micron.

② Grinding: The principle of mutual grinding of fitting parts is used to select and process irregular raised parts on the machined surface. Abrasive particle diameter, cutting force and cutting heat can be precisely controlled, so it is the machining method that obtains the highest precision in precision machining technology. Hydraulic or pneumatic fitting parts in precision servo parts of aircraft, and bearing parts of dynamic pressure gyro motors are all processed by this method to achieve an accuracy of 0.1 or even 0.01 microns and a microscopic roughness of 0.005 microns.

③ Fine milling: used for machining aluminum or beryllium alloy structural parts with complex shapes. High mutual position accuracy is obtained by relying on the accuracy of the guide rail and spindle of the machine tool. High-speed milling with a carefully ground diamond cutter head can obtain accurate mirror surfaces.

④ Fine grinding: used for machining shaft or hole parts. Most of these parts are made of hardened steel, which has a high hardness. Most high-precision grinding machine spindles use hydrostatic or hydrodynamic liquid bearings to ensure high stability. The ultimate accuracy of grinding is not only affected by the stiffness of the machine spindle and bed, but also related to the selection and balance of the grinding wheel and the machining accuracy of the center hole of the workpiece. Fine grinding can obtain a dimensional accuracy of 1 micron and a roundness of 0.5 micron.

In the aerospace industry, precision parts processing is mainly used to process precision mechanical parts in aircraft control equipment, such as precision fittings in hydraulic and pneumatic servo mechanisms, gyroscope frames, shells, air and liquid floating bearing components, and floats.

The structure of aircraft precision parts is complex, the stiffness is small, the accuracy is high, and the proportion of difficult-to-machine materials is large.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque