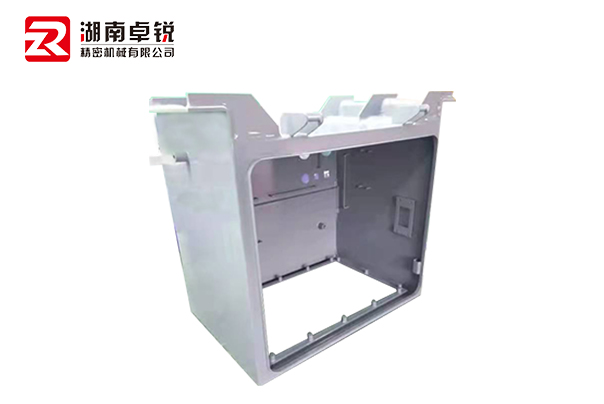

Chassis cabinet Sheet Metal Processing is the process of forming metal plates into the desired shape using a variety of different manufacturing methods, including cutting, bending, surface treatment, assembly and many other steps. Usually, the process from chassis cabinet sheet metal to metal products starts with CAD drawing. After the drawing is completed, it goes through the sheet metal manufacturing process to make a variety of parts. Nowadays, the application range of sheet metal chassis cabinets is very wide, suitable for different fields. The application of sheet metal chassis can also solve more practical problems and play a greater role. However, to ensure the quality of processing, it is also necessary to pay attention to a certain understanding of the processing points during processing and production, so that after the processing operation is completed, more ideal results can be achieved and the processing and manufacturing quality of sheet metal chassis can be guaranteed. The editor of the sheet metal processing company will introduce the main points and process standards of the processing operation of the sheet metal chassis and cabinet. Sheet metal shell processing

During the processing process, the angle of the sheet metal parts must be determined first. Before processing, the staff needs to determine the rake angle according to the actual needs, which can improve the strain capacity of the tool, reduce wear and effectively improve the processing efficiency. In addition, the wear resistance of the tool will also be greatly improved along with the processing and production operations, so the staff needs to determine the angle of the machining rake angle and adjust it according to the product processing requirements.

During the processing process, the angle of the sheet metal parts must be determined first. Before processing, the staff needs to determine the rake angle according to the actual needs, which can improve the strain capacity of the tool, reduce wear and effectively improve the processing efficiency. In addition, the wear resistance of the tool will also be greatly improved along with the processing and production operations, so the staff needs to determine the angle of the machining rake angle and adjust it according to the product processing requirements.

In addition, during the processing of sheet metal chassis, attention should also be paid to determine the position of the back corner. During the processing, the cutting operation cannot be ignored. If the cutting operation angle is too small, it will affect the size of the contact area, and the processing range will be limited. In areas with higher temperatures, centralized control is required to avoid excessive tool wear, so as to achieve better Quality Standards.

Nowadays, the processing of sheet metal chassis has attracted the attention of users. In order to ensure quality, it is necessary to strictly follow the processing process, and at the same time, the processing process must be completed in accordance with standard procedures, so as to make the product quality better and bring more benefits to the manufacturer. Ensure that the product quality is in line with market demand.

During the processing of sheet metal chassis cabinets, it is also necessary to implement physical, chemical and other design methods. In this way, the plate box structure can be guaranteed to meet stable requirements, and the strength of the equipment can also be improved. During the processing operation, it is also necessary to pay attention to improving the impact resistance of the product and the anti-corrosion effect, which directly affect the use of the equipment. These problems cannot be ignored during processing and production.

Nowadays, the requirements for sheet metal chassis processing are getting higher and higher. During processing and production, attention should also be paid to the selection of safety protection work to ensure that the processing operation is completed within a safe range. In addition, the installation, operation and maintenance of equipment should also be carried out in accordance with the standard process. These are the process methods to be paid attention to during processing operations.

In the processing of sheet metal chassis cabinets, production, assembly, debugging and other links cannot be ignored, and each process must meet the standards, which is an important matter when processing. Today, sheet metal chassis processing operations will be developed in strict accordance with the degree of standardization and serialization, which is not only conducive to improving product quality, but also increases efficiency in practical applications and meets the requirements of industrial applications.

The above-mentioned content is related to the main points and process standards of sheet metal chassis cabinet processing operations. I hope it can be helpful to you. If you want to know more about sheet metal chassis cabinets, you can contact online customer service. We will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole