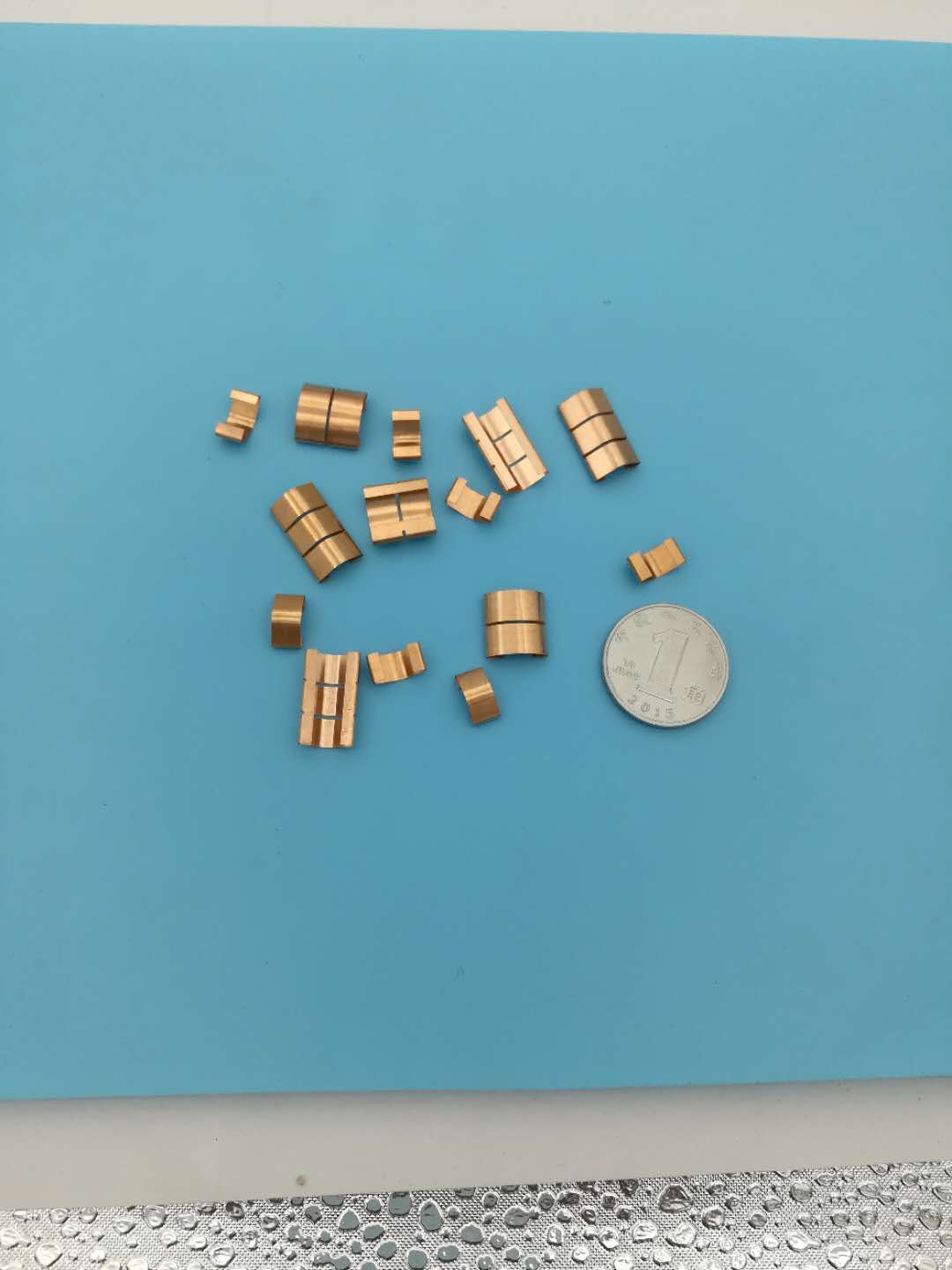

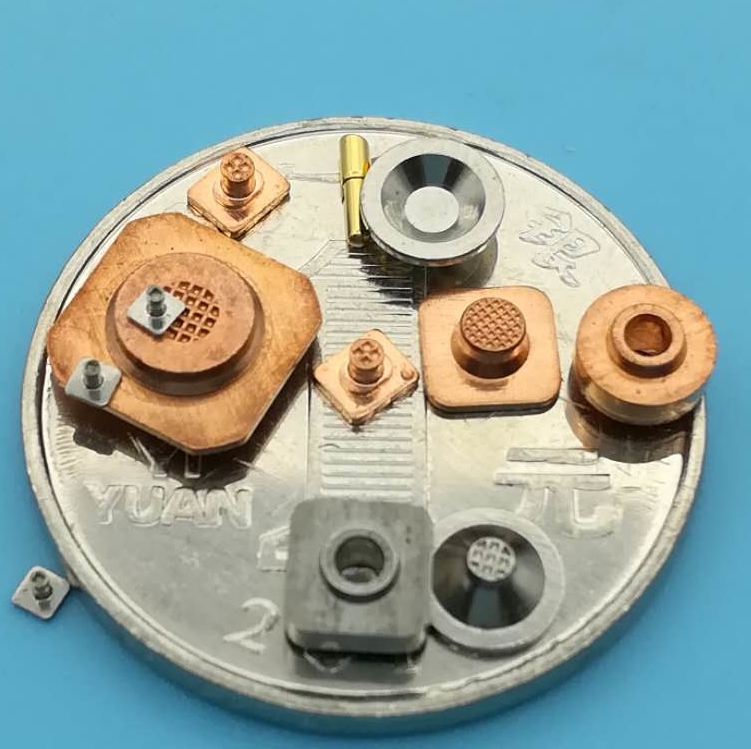

In the process of laser cutting of products, the processing speed of Sheet Metal Processing companies is very tight. If the speed control is not suitable during the processing of products, it is easy to affect the cost and also have a negative impact on the actual application results of products. Therefore, in the processing of products, many sheet metal processing manufacturers will pass sheet metal processing. Since this process method can greatly improve the speed and ensure the processing quality of products, the application restrictions are also very extensive. It can be used for numerical control and other equipment, and can also realize the needs of automatic processing and manufacturing

Nowadays, the operation process of sheet metal processing is also more simple and convenient. No complicated operation process is required to achieve the processing goal, and the processing process can also be determined according to the actual needs of the manufacturer. Therefore, in the process of processing products suitable for complex shapes, the product processing limit can also be doubled.

Sheet metal processing companies can also ensure the processing accuracy, so places with higher requirements for product processing accuracy can be processed by this processing method, which can make the processing quality of the product more reasonable, and the thickness and specifications of the product can better meet the actual needs. It can also effectively improve the processing character of the product. These are the main advantages of choosing this process method and the benefits it can bring to the manufacturing work.

Sheet metal processing companies can also ensure the processing accuracy, so places with higher requirements for product processing accuracy can be processed by this processing method, which can make the processing quality of the product more reasonable, and the thickness and specifications of the product can better meet the actual needs. It can also effectively improve the processing character of the product. These are the main advantages of choosing this process method and the benefits it can bring to the manufacturing work.

The anti-rust skills of sheet metal processing companies include the following suggestions:

1. Although deoiling is done with weak alkali, it should not contain caustic soda as much as possible. The TAL should be controlled at about 15POINT, and the pH should not exceed 12.

2. The pickling passivation step can accept sulfur pickling passivation, the pickling passivation time is not long, and the application of ammonium sulfate is just right.

3. After pickling and passivation, apply it to 1-2 sodium carbonate.

4. Surface adjustment is usually used to analyze chemical raw materials with sulfuric acid at an equivalent concentration of 1 to 2 degrees.

5. Zinc-based phosphating acid is very limited, try prepreg: TA: 45, FA: 1.3AC: 8 (20cc fermentation tube).

6. Construction projects do not need to be cleaned and tidy, and hand washing should maintain overflow.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole