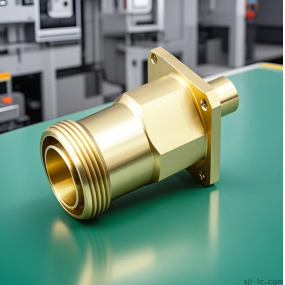

Intelligent manufacturing technology is the integration of artificial intelligence into all aspects of the manufacturing process. By simulating the intelligent activities of human experts, it replaces or extends part of the mental work in the manufacturing system. During the manufacturing process, the system can automatically monitor its operating status, and automatically adjust its parameters under external interference or internal excitation to achieve the best state and have self-organization ability. The new numerical control EDM machine adopts fuzzy control technology and expert system intelligent control technology.

Shenzhen precision parts machining fuzzy control technology is monitored by a computer to determine the state of the EDM gap, and automatically selects the machining conditions to achieve the highest machining efficiency within the range of maintaining a stable arc; automatically monitors the machining process to achieve the most stable machining process control technology. An expert system using man-machine dialogue can automatically create a machining program after reasonably entering the set value according to the processing conditions and requirements, and select the best combination of processing conditions for processing.

Shenzhen precision parts machining fuzzy control technology is monitored by a computer to determine the state of the EDM gap, and automatically selects the machining conditions to achieve the highest machining efficiency within the range of maintaining a stable arc; automatically monitors the machining process to achieve the most stable machining process control technology. An expert system using man-machine dialogue can automatically create a machining program after reasonably entering the set value according to the processing conditions and requirements, and select the best combination of processing conditions for processing.

Online automatic monitoring and adjustment of the machining process to achieve the optimal control of the machining process of precision parts. When the expert system detects the machining conditions, as long as the input processing shape, electrode and workpiece material, machining position, target roughness value, electrode scaling amount, shaking method, taper value and other indicators, it can automatically calculate and configure the optimal machining conditions. The application of expert system intelligent technology makes the machine tool operation easier and requires less technical level of the operator. Shenzhen precision parts machining

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque