The process of precision Sheet Metal Processing mainly includes the following steps:

Engineering Drawing: Professional sheet metal engineers draw 2D or 3D drawings of products with the help of CAD software, marking the size, shape and position of each part in detail, providing an accurate basis for subsequent processing.

Engineering Drawing: Professional sheet metal engineers draw 2D or 3D drawings of products with the help of CAD software, marking the size, shape and position of each part in detail, providing an accurate basis for subsequent processing.

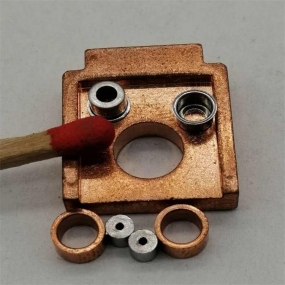

Blanking: According to the design drawings, large pieces of raw materials are cut into the required size and shape by using equipment such as shearing machines, punches, and laser cutting machines.

Forming: through bending, stretching, stamping and spinning processes, the flat material is processed into the desired three-dimensional shape.

Connection: Welding, riveting, bolting, etc. are used to connect multiple parts into a complete product.

Connection: Welding, riveting, bolting, etc. are used to connect multiple parts into a complete product.

Surface treatment: spray painting, electroplating, powder spraying, etc. on the processed parts to improve the corrosion resistance, hardness and appearance quality of the parts.

Quality inspection: Conduct a comprehensive quality inspection of the finished product, including dimensional measurement, mechanical property testing, and appearance inspection, to ensure that the product quality meets the design requirements.

During the entire processing process, every step needs to strictly follow the process specifications and operating procedures to ensure that the processed products are of high precision and quality. At the same time, new technologies and equipment need to be continuously introduced to improve production efficiency and product quality and meet market demand.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque